HomeProductsInflatable SealsInflatable Seal For Annealing ...

Inflatable Seal For Annealing Furnaces

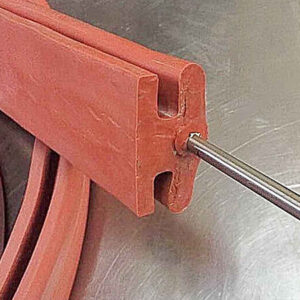

Western Polyrub Silicone Inflatable Seal For Use Between The Cover And Base Of A Heat Treating Furnace.

Inflatable Seal For Annealing Furnaces

Western Polyrub Silicone Inflatable Seal For Use Between The Cover And Base Of A Heat Treating Furnace.

The Seal Includes An Annular Fluid-impervious Member Mounted On The Base. Brass Valves Are Provided To Inflate And Deflate The Annular Member. In The Inflated Position, The Annular Member Extends Between The Cover And The Base To Provide A Tight Seal. The Casing Of The Member Is Made Of A Metal Or Any Other Material.

The Use Of Bell-type Annealing Furnaces For Heat Treating Coiled Strips Of Material Has Become Widespread In The Art. These Heat Treating Furnaces Include A Base Of One Or More Pedestals On Which The Coiled Strips Of Material Which Are To Be Heat Treated Are Placed. An Inner Cover Is Placed Over These Coiled Strips Of Material, And It Is Necessary In Most Instances To Seal The Coils Within The Inner Cover To Provide A Controlled Atmosphere Therein.

Why Inflatable Seal?

It Gives 100% Sealing

No Proper Machining Of Lead

Easy To Operate And Install

Save Replacement Time And Long Life

leading manufacturers of fabric inflatable seal

Today western polyrub stand out as leading manufacturers of fabric inflatable seal who make seals with hand built and fully moulded with fabric reinforcement inside make seal so tough that can withstand pressure up to 50 Kgcm2 Fabric Reinforced Rubber Seals Are Effective Where Moderate- To High-pressure Is Applied(we make seal up to 50bar bursting pressure ) , Such As In Heavy Industrial, Environmental, Technical And Laboratory Environments,marine,nuclear Region A Variety Of Reinforcing Fabrics Are Available And Determined By Factors Such As Temperature And Pressure.

Fabric inflatable seal moulded

Wespo also provide fabric inflatable seal moulded with rubber nozzle for flexibility and longer life if clients demand Western Polyrub Offers Technical Guidance To Determine The Appropriate Design, Manufacturing And Material Composition. The Fabric Inflatable Must Withstand Environmental Factors And Perform Using Air Or Gas Controlled Mechanisms Under Pressure. The Environment And Structure Will Affect The Choice

OFFSHORE APPLICATION

Western polyrub has developed technology to used fabric reinforced inflatable seal in a number of critical applications including offshore production, storage and offloading (FPSO); anchoring drill rigs to the seabed; gas loading systems; pipeline welding; and watertight doors and panel High -pressure inflatable seals are designed to fit in metal retaining grooves, allowing axial, external radial and internal radial expansion, These seals typically can withstand pressures of up to 8 bar, and are suitable for sealing clearances from 2-10mm.

Applications Of Inflatable Seal For Annealing Furnaces

- Multiple Application In The Process Industry

Features

- NBR, Buna-N

SKETCH DRAWING

Send your sketch or drawing

MATERIAL

Choose the Material

SPECIAL FEATURE

Add the special feature

FINAL PRODUCT

We will deliver your product quickly.