HomeRubber Expansion Bellow And Jo...

Rubber Expansion Bellow And Joints

WESPO MAKE EXPANSION JOINTS IN ALL POLYMER WITH RELEVANT CERTIFICATION

Introduction

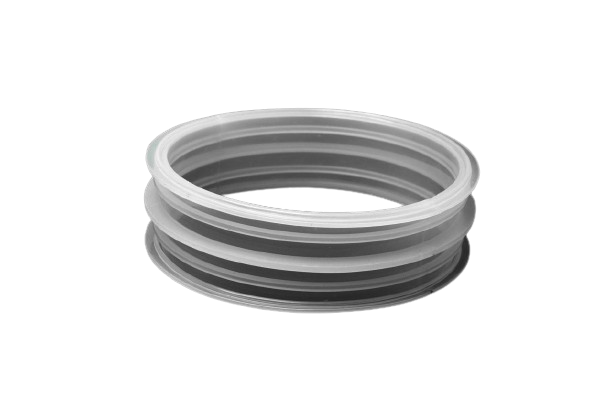

Rubber Expansion Bellow And Joints

Mainly Consulting Engineers, Mechanical Contractors, Pressure Vessel Designers, Plant Engineers And Turn-Key Construction Firms Have Specified And Used Rubber Expansion Joints For Several Years.

They Are Installed To Allow Movement On Piping Runs, Protect Piping From Expansion Reacting And Insure Efficient And Economical On Stream Operations.

Rubber Expansion Bellow And Joints For Your Every Need

WESPO Rubber Expansion Joints Offer Proven Ways To Accommodate Pressure Loads, Relieve Movement Stresses, Modate Pressure Loads, Relieve Movement Stresses, Isolate Vibration, Reduce Noise, Prolong The Life Of Motive Equipment And Compensate For Misalignment A Plant Goes On Stream.

WESPO RUBBER EXPANSION BELLOW.

- 30+ Years Experience

- Design Guidance

- Array Of Products

Products Benefits

Latest Technology

We use latest technology for rubber mixing, adhesive chemistry and bonding process.

Expert Chemical Engineers

We use latest technology for rubber mixing, adhesive chemistry and bonding process.

Research & Development

We use latest technology for rubber mixing, adhesive chemistry and bonding process.

Rubber Expansion Bellow And Joints

Rubber Expansion Bellow And Joints For Your Every Need

Non Reinforced Inflatable Seals

Wespo Inflatable door seal is a reinforced elastomeric tube or without reinforced (depend on pressure) custom molded in a round concave, convoluted or flat configuration . it is designed to round out with the introduction of an inflation medium to form a tight barrier between a mounting and striking surface.

Fabric Reinforced Inflatable Seal

A fabric reinforced seal is a completely molded seal which is built around the same operating principles as a homogeneous inflatable seal. The addition of fabric helps increase the amount of internal pressure by which the seal can operate, where higher pressures are required in a non-enclosed form.

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.