HomeProductsMolded Rubber ProductsNon Reinforced Inflatable Seal...

Inflatable Seals

Wespo Inflatable seals are either fully rubber moulded or rubber moulded with fabric reinforced if pressure is high.

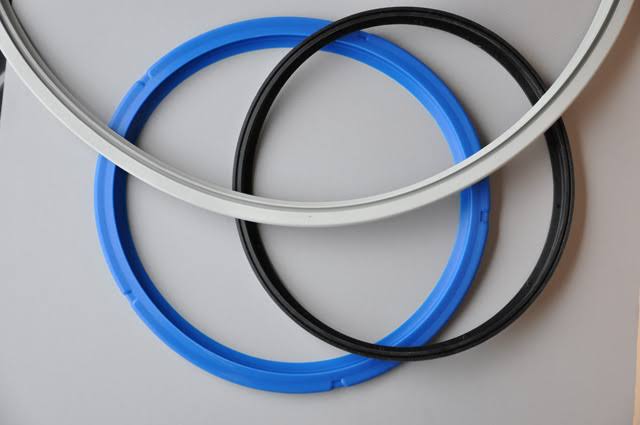

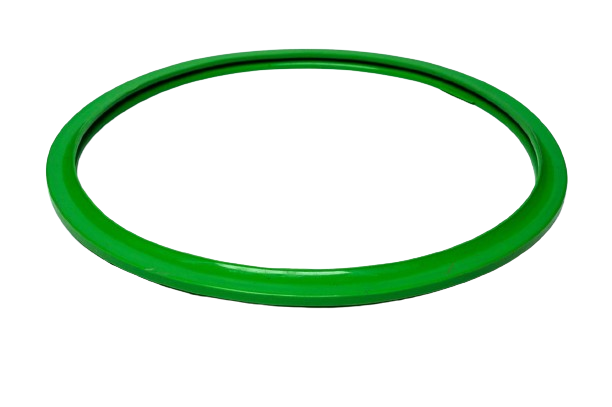

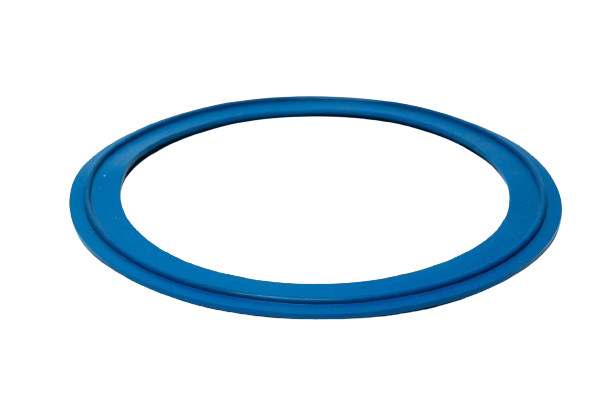

Non Reinforced Inflatable Seals

Fully molded rubber wespo inflatable seal is specially designed to provide a solution to a many leakages either chemical,water,air or gas Wespo inflatable seal can be used to make :-

Wespo fabric reinforced inflatable seal specially designed which inflate and deflate with high air pressure Continuously without tear or leakage.

Seals come in three main configurations –

1)Concave

2)Convoluted,

3) Flat.

Seals comes in 5 Types :

1) Footless seal

2) Fasten in seal

3) Snap in seal

4) Bonded bottom seal

5) Slot fit seal

Wespo branded Inflatable seals can be used for a variety of applications where sealing two surfaces that move in relationship to each other is required. By introducing a medium such as air or fluid, a rubber seal will begin to expand at a specified rate until a determined size of expansion is achieved.

The rates and sizes of the expansion of an inflatable seal are pre-determined by one of the many shapes and sizes we have readily available. For unique or custom applications, we can engineer a solution.

Nearly all inflatable seals are custom fabricated for a specified application, and we can use many of our standard profiles to develop an inflatable seal to a custom required working parameter. By utilizing a standard profile, both time and money are save

Certification –

Wespo inflatable are independently pressure tested and supplied with a supporting pressure ‘Test Certificate’. And material test certificate , for Pharma and food grade application wespo providing material FDA and EURO certificate .

Wespo seals tested at different pressure from 1 bar to 6 bar pressure (under close condition in metal rig ) dependent on the seal type and/or customer specifications wespo seal comes with identification number which providing detailed traceability for each individual seal supplied with pressure

WSDS antistatic silicone inflatable seal for ATX zone is available in blue or white colour.

leading manufacturers of fabric inflatable seal

Today western polyrub stand out as leading manufacturers of fabric inflatable seal who make seals with hand built and fully moulded with fabric reinforcement inside make seal so tough that can withstand pressure up to 50 Kgcm2 Fabric Reinforced Rubber Seals Are Effective Where Moderate- To High-pressure Is Applied(we make seal up to 50bar bursting pressure ) , Such As In Heavy Industrial, Environmental, Technical And Laboratory Environments,marine,nuclear Region A Variety Of Reinforcing Fabrics Are Available And Determined By Factors Such As Temperature And Pressure.

Fabric inflatable seal moulded

Wespo also provide fabric inflatable seal moulded with rubber nozzle for flexibility and longer life if clients demand Western Polyrub Offers Technical Guidance To Determine The Appropriate Design, Manufacturing And Material Composition. The Fabric Inflatable Must Withstand Environmental Factors And Perform Using Air Or Gas Controlled Mechanisms Under Pressure. The Environment And Structure Will Affect The Choice

OFFSHORE APPLICATION

Western polyrub has developed technology to used fabric reinforced inflatable seal in a number of critical applications including offshore production, storage and offloading (FPSO); anchoring drill rigs to the seabed; gas loading systems; pipeline welding; and watertight doors and panel High -pressure inflatable seals are designed to fit in metal retaining grooves, allowing axial, external radial and internal radial expansion, These seals typically can withstand pressures of up to 8 bar, and are suitable for sealing clearances from 2-10mm.

Applications of Non Reinforced Inflatable Seals

- Aerospace, Phonic Isolation, Aircraft Access Doors, Cockpit Canopies, Portholes

- Leak-tight panels

- Defense

- Industrial Applications

- Land-based turbines

- Cofferdams

- Pneumatic conveyors (bagging hoppers, valve gates)

- Oil & Gas

- Sliding or quick-locking doors (autoclaves, sterilizers)

- Centrifugal filters (access doors and drainage hoppers)

- Nuclear

- Movable cofferdam

- Bulkheads, Storage and transport containers

- Nuclear power plant (equipment or personnel chambers)

- Pharmaceutical Isothermal chambers

- Clean rooms

Features :- (Materials)

- Polymer -

- Butyl

- Chloroprene

- Epichlorohydrin

- Ethylene-Propylene

- Fkm (Viton®)

- Natural Rubber

- Nitrile (Buna N)

- Polyurethane

- Silicone

- Fabric -

- Nylon

- Dacron

- Nomex

- Kevlar

SKETCH DRAWING

Send your sketch or drawing

MATERIAL

Choose the Material

SPECIAL FEATURE

Add the special feature

FINAL PRODUCT

We will deliver your product quickly.