HomeGaskets

Gaskets

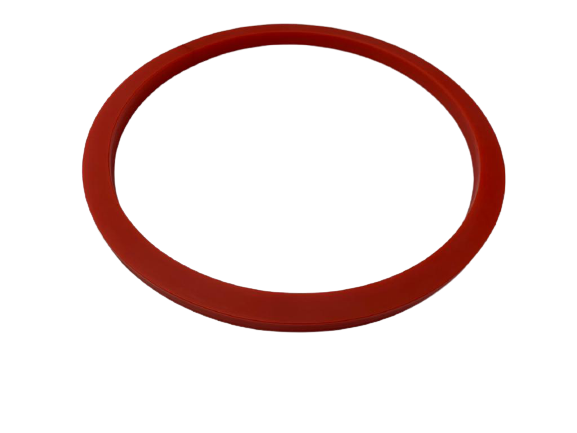

Wespo gaskets are built to do more than just fit—they’re crafted to last. Designed to handle pressure, temperature, and tough conditions, they deliver reliable sealing across industries where every seal counts.

Gaskets That Seal with Confidence

Western Polyrub Offers Custom Engineered Rubber Solutions To Customers Across The Globe.

The function of the autoclave door gasket is one of the most important features in any steam sterilizer and autoclave its work to serve the seal to restrict steam within chambar . Wespo makes wide range of steriliser and autoclave gaskets for standard and custom applications. Our steriliser and autoclave gaskets are engineered to resist the high temperature steam environments and found in most commercial ,medical and hospital autoclave systems.

Jet Dyeing Yarn Dyeing And Beam Dyeing Autoclave Gasket

In very high speed spinning machines generate more friction thus giving additional heat to the yarn and as a result of such heat transfer the yarn moisture content is vaporized. Rising speeds in spinning result in decreased yarn quality for other processes and it is well known that dry yarns have worse properties.

Wespo rubber gasket is an essential component that effectively seals against the flow of liquids and gases. They are necessary if you want to connect two surfaces that have some irregularities. One striking feature of a gasket is that it is flexible (manipulable) such that it can warp into tight spaces and make a perfect seal. The various properties of wespo rubber gaskets make them suitable for a wide range of industries including food processing, oil and gas, and water supply among other areas. Each type of gasket has a special property depending on its material. It means that in buying gaskets, you will have to look out for characteristic features that you can take advantage of. For a gasket to work effectively and seal leaks tightly, it should be compressed adequately to create a pressure-tight barrier. This way, it can protect the content inside the seal. An elastomeric gasket acts as a system that seals against the release or inlet of fluids (gases and liquids). Gaskets are ideal options for filling deformities and joining surfaces together. Because they are designed to occupy spaces between surfaces, many gaskets are created from materials that can be deformed.

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.