HomeMolded Rubber Products

Molded Rubber Products

Wespo offer a variety of precision engineered rubber products that ensure sealing solutions for diverse industrial applications.Our products come in your desire shapes, sizes and materials to perfectly suit your needs.

Introduction

Molded Rubber Products

Western Polyrub Offers Custom Engineered Solutions To Customers Across The Globe. With Over 30 Years Of Experience, We Offer A Wide Range Of Custom Molded Rubber Products And Extruded rubber Profiles.

Our In-House Team Of Design Engineers e Manufacture Dies In-House On The VMC With 3-Micron Precision To Meet Perfection. Western polyrub Chemical Engineering Team Is Involved In Every Stage From Tooling To Formulating Rubber Compounds To Achieve The Desired Results.

Wespo has an Impressive setup with a factory covering 20000 square feet area and in house lab for making hose,orings,seals,gaskets,plug,diaphragm, ,washer,cushion,mount,bushing,bumper,metal bonded,and many pass through strict quality control and efficient production processes

wespo makes environmentally friendly molded rubber products and to pursue the advance management level

- 30+ Years Experience

- Design Guidance

- Array Of Products

Products Benefits

Thermally Conductive

We use latest technology for rubber mixing, adhesive chemistry and bonding process.

Anti-Wear Design

We use latest technology for rubber mixing, adhesive chemistry and bonding process.

Durable Quality

We use latest technology for rubber mixing, adhesive chemistry and bonding process.

Wide range of molded rubber products from Wespo

Western Polyrub Offers Custom Engineered Rubber Solutions To Customers Across The Globe.

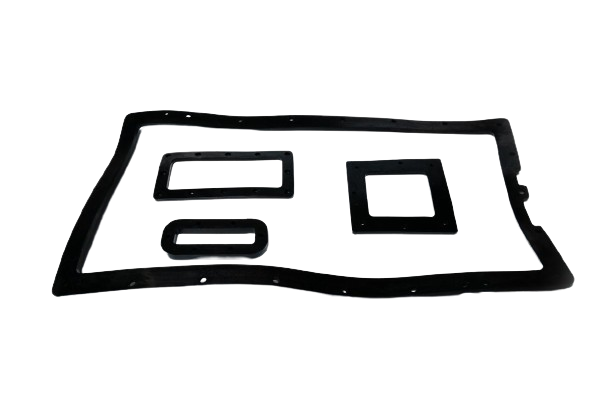

Autoclaves Door Gaskets

The function of the autoclave door gasket is one of the most important features in any steam sterilizer and autoclave its work to serve the seal to restrict steam within chambar . Wespo makes wide range of steriliser and autoclave gaskets for standard and custom applications. Our steriliser and autoclave gaskets are engineered to resist the high temperature steam environments and found in most commercial ,medical and hospital autoclave systems.

Jet Dyeing Yarn Dyeing And Beam Dyeing Autoclave Gasket

In very high speed spinning machines generate more friction thus giving additional heat to the yarn and as a result of such heat transfer the yarn moisture content is vaporized. Rising speeds in spinning result in decreased yarn quality for other processes and it is well known that dry yarns have worse properties.

Rubber Gasket

Wespo rubber gasket is an essential component that effectively seals against the flow of liquids and gases. They are necessary if you want to connect two surfaces that have some irregularities. One striking feature of a gasket is that it is flexible (manipulable) such that it can warp into tight spaces and make a perfect seal. The various properties of wespo rubber gaskets make them suitable for a wide range of industries including food processing, oil and gas, and water supply among other areas. Each type of gasket has a special property depending on its material. It means that in buying gaskets, you will have to look out for characteristic features that you can take advantage of. For a gasket to work effectively and seal leaks tightly, it should be compressed adequately to create a pressure-tight barrier. This way, it can protect the content inside the seal. An elastomeric gasket acts as a system that seals against the release or inlet of fluids (gases and liquids). Gaskets are ideal options for filling deformities and joining surfaces together. Because they are designed to occupy spaces between surfaces, many gaskets are created from materials that can be deformed.

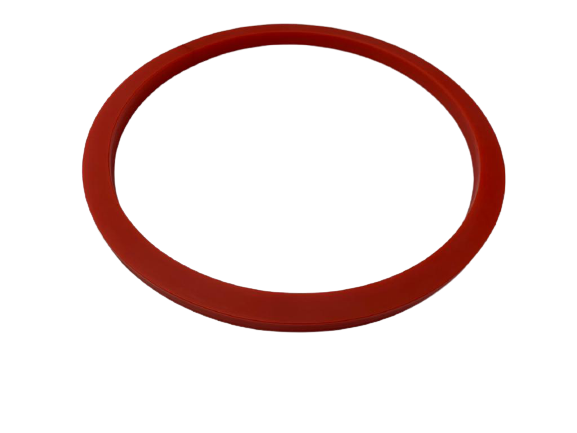

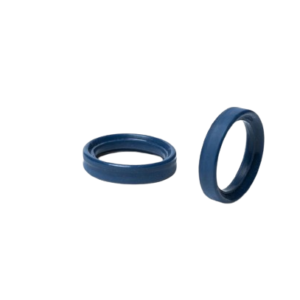

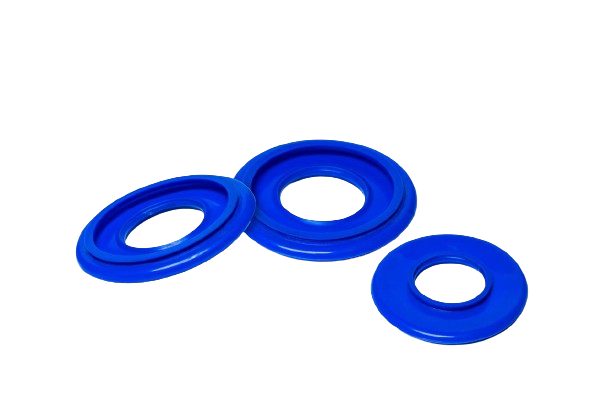

Camlock seal

Western polyrub offers camlock gasket seals in Buna (Nitrile), Viton, Epdm,Silicone metal detectable FEP/PFA Encapsulated, and wespoprene (Satntoprene) Wespo white food grade chemlock seal with fda certificate available on request.

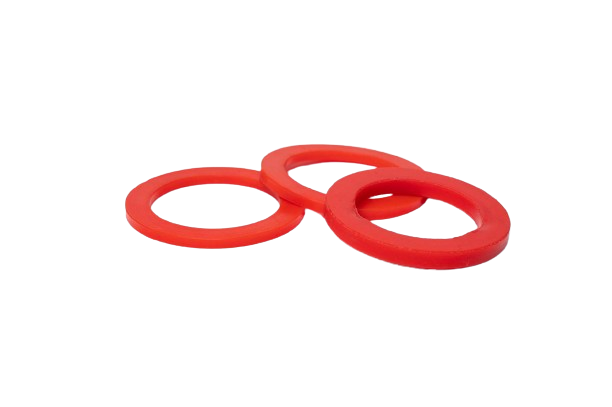

Mini Clamp seal

Mini clamp gasket widely used in processing pipeline systems for the food, dairy, beverage, pharmaceutical and biotech industries.

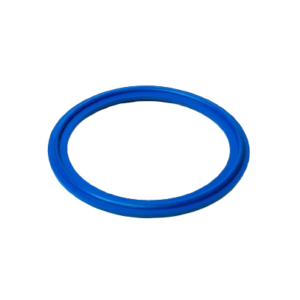

Triclover gasket

Western polyrub Triclover gasket are used for connecting two pipes to transfer liquid or powder mainly in pharmaceutical, food ,beverage, and chemical industries.

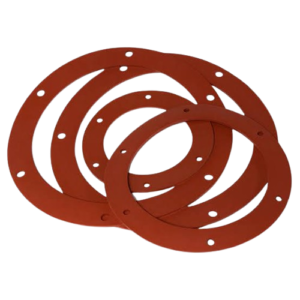

Silicone Flange gasket

Western Polyrub manufacture silicone flange gasket in a wide variety of food grade silicone grades (with fda and euro approved certificate )from 30 to 90 hardness in any colour and thicknesses from 0.2 mm to 100mm

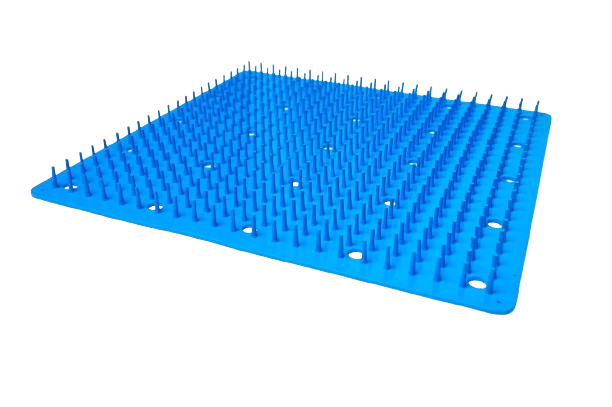

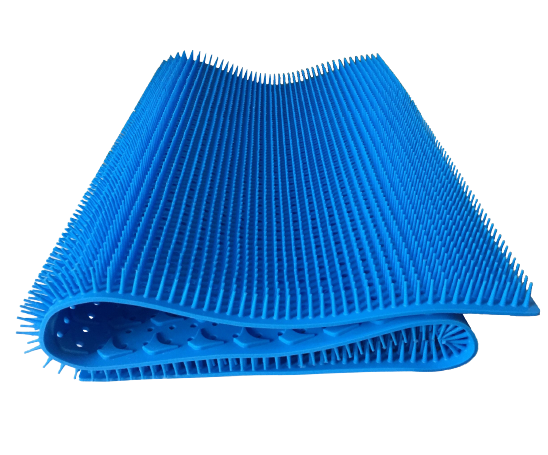

Silicone Mat For Sterilization Tray

Western sterilisation silicone pin mats ( also called instrument sterilisation container silicone mats or medical silicone mator ophthalmic silicone mat and trays)

Silicone Tapered Plug

Western polyrub silicone tapered plugs (sometimes called silicone corks or stoppers) are ideal for almost any masking situation involving threaded or non-threaded blind or through holes. Made from fully cured silicone to avoid leaching into plating tanks.

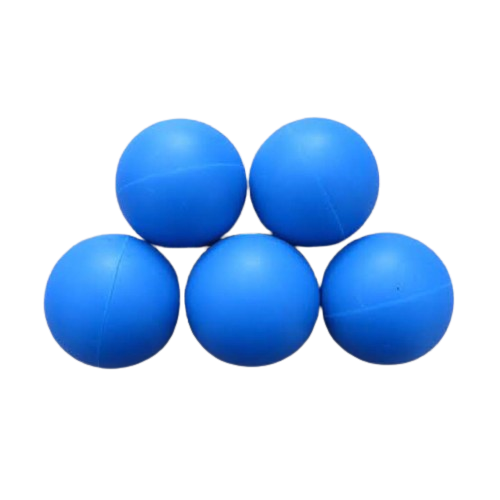

Screen Cleaning Ball

Wespo screen cleaning ball function Is to knock the Vibrating Screen In the middle Of The Vibrating Screen and the screen, so that the Material Attached To The Screen Surface Can Come Off The Screen and avoid blocking The Screen To Affect The Screening yield and accuracy.

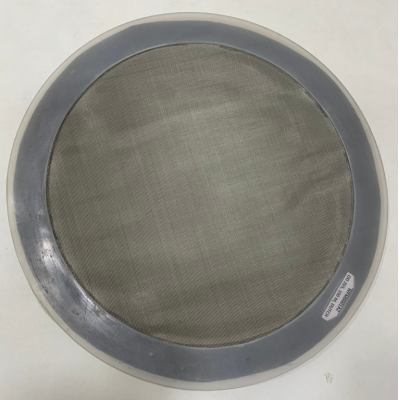

Silicone Moulded Dutch Sieves For Fbd

Wespo Silicone Moulded dutch sieves for fbd is made from transparent fda approved silicone rubber which are free from toxic Lead & Tin metals.

Rubber Diaphragm

Fabric reinforced rubber diaphragm are our expertise from last 30 plus years. We are manufacturers and exporters of rubber diaphragms in natural and synthetic rubber with or without fabrics reinforced and metal ,plastic , carbon or ptfe bonded with matching methodology.

Dome Valve seal

Western inflatable dome valves seals ensure leak-proof sealing in continuous operation while operating to isolate a pressure differential.

Victaulic Gasket

Victaulic gasket grooved piping concept is simple and reliable.

Butterfly valve gasket

Wespo butterfly valve gasket is an important component for blocking all three potential leakage paths: the sealing of pipes, flanges and operating shafts, in shut-off valves, flap valves and disk valves. In their materials and design, they must be configured optimally for the respective application.

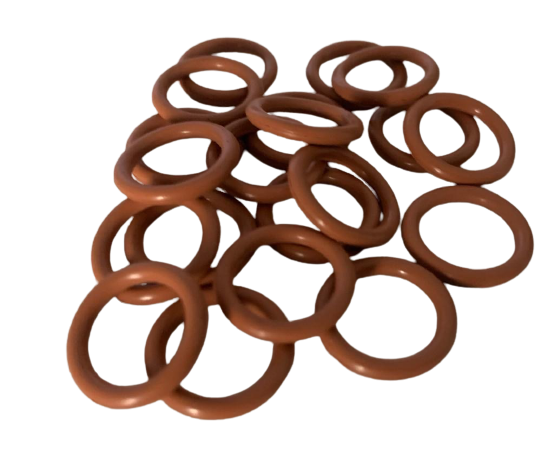

Rubber O Rings

Wespo make custom o rings as per client requirements ,o ring will be either moulded or spliced from cord and vulcanised joint or join with adhesive depending upon application.

FFKM Rubber Orings

Wespo manufacture, supply and Export Perfluoroelastomer (FFKM) kalrez O-Ring which is manufactured with the best quality material and are offered as per client specifications in Mumbai Our ffkm Rubber orings are customized as per the client-specific requirements in various thicknesses, lengths and sizes. Equipped with high-end facilities and a team of highly qualified and experienced professionals wespo deliver the best of quality at the most affordable cost.

Aflas Genuine Viton Moulded And Extruded Parts

Western polyrub are manufacturer and exporters of moulded and extruded parts from above new generation polymer.

Silicone Bulb For ECG

Wespo is OE manufacturer and supplier of silicone bulb for ECG

Rubber Parts For Solar Industry

Solar energy has become increasingly popular as an alternative energy source in recent years. Solar photovoltaic (pv) modules use flat panels, parabolic mirrors, fresnel lenses, and flexible thin-film panels to collect and convert sunlight into electricity. Electricity generated from these sources is then converted from dc to ac for distribution and daily use.

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.