HomeMetal Detectable Rubber Produc...

Metal Detectable Rubber Products

Metal Detectable Rubber Products And X-Ray Detectable Rubber Compounds Are Essential To Reduce The Risk Of Contamination In The Food And Beverage Industries.

Introduction

Metal Detectable Rubber Products

Metal Detectable And X-Ray Detectable Rubber Compounds Are Essential To Reduce The Risk Of Contamination In The Food And Beverage Industries.

The Early Detection And Removal Made Possible With These Types Of Elastomers Reduces The Risk Of Contaminated Product Ever Reaching The Wider Supply Chain.

100% Leak Proof Inflatable Seals For Every Application Custom Engineered. Precision Built.

Our Metal Detectable O Rings And Seals Are Offered In A Range Of Shapes And Sizes, With A Variety Of Elastomer Grades Available.

Fully Molded Construction And Fabric Reinforcement Makes Our.

- 30+ Years Experience

- Design Guidance

- Array Of Products

Products Benefits

Easy Detection Of Lost Fragments Of Elastomer

FDA Compliant For Use With Drink And Food

Large Operating Temperature Range

Metal Detectable Rubber Products

Our Metal Detectable O Rings Seals,gasket,extrusion are available In wide range with required shapes and sizes, With a variety of Elastomer Grades  .

.

Metal detectable Silicone o rings

Wespo metadect metal and x-ray detectable silicone rubber o rings will detected by integrated metal detectors fitted along the processing lines

Metal detectable Tri-Clamp Gasket

Wespo metal detectable gasket manufactured by insuring products safety and integrity as outlined by the food safety norms

Metal detectable silicone ball

Wespo metal detectable silicone , nbr & polyurethane ball in hardness from 70 – 90 with fda & euro certificates

Metal detectable ear plug

Providing proper hearing protection for employees can be challenging especially when this type of facility requires strict health, sanitation and safety requirements. This is why metal detectable earplugs can be the ideal method of hearing protection in food manufacturing facilities—and they offer more than just hearing protection.

Metal detectable silicone sponge extrusion

Western polyrub metal detectable silicone sponge extrusion products is widely used in the food,pharma, drink and dairy industry ,meet fda and euro approval certificate.

Metal detectable silicone cord

Western metal detectable silicone rubber cord comes in a hardness of 50 shore A to 80 shore A Fully compliant to food grade industry standards.

Metal detectable silicone extrusion

Western polyrub manufacture metal detectable silicone rubber extrusion in any shape(more then 5000 ready shape available) with in 48 hours with all certificate

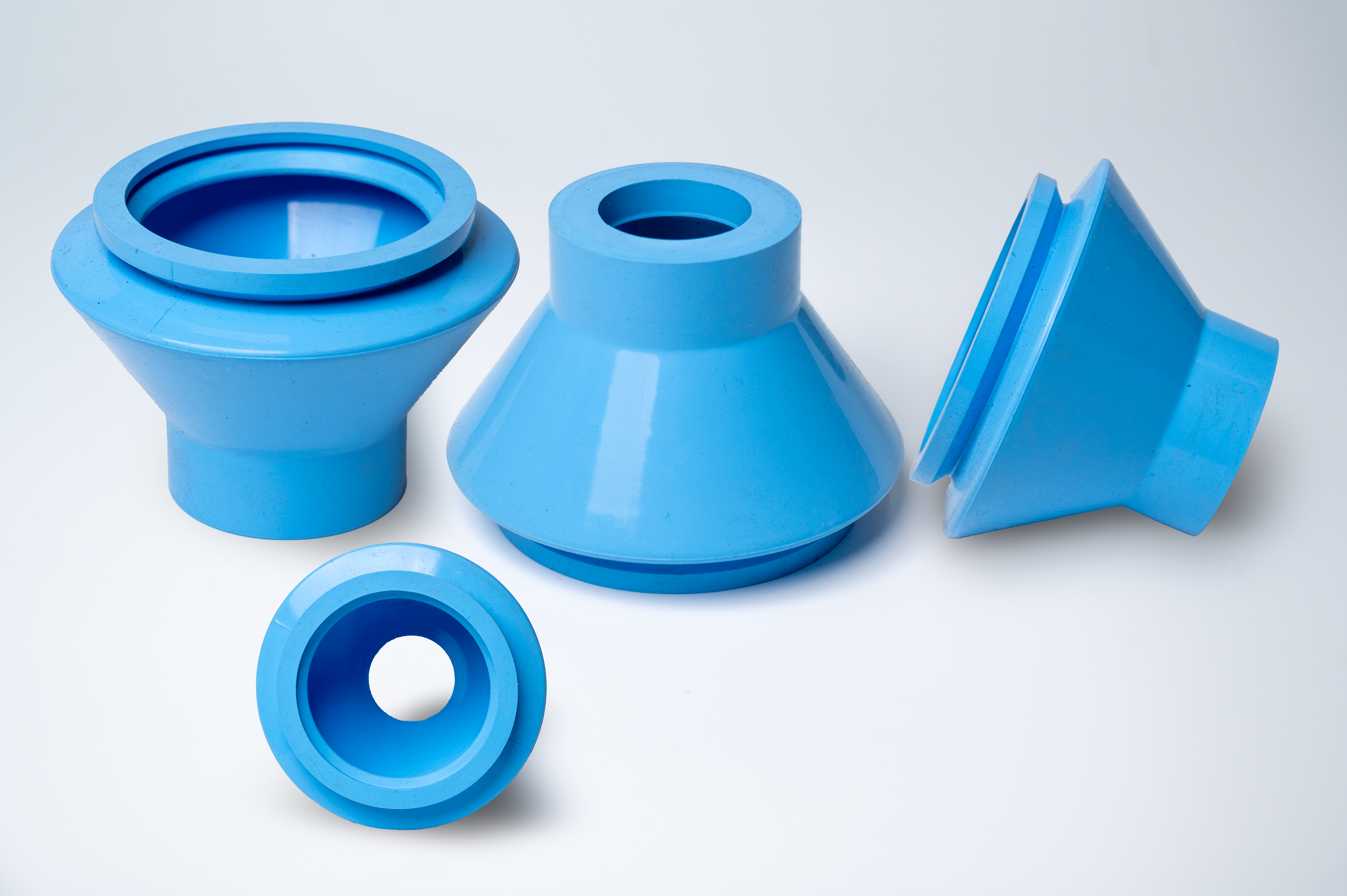

Metal detectable depanner Cups

Western make Metal detectable depanner bellow from food grade silicone rubber available in any colour with fda certificate.

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.