HomeRubber Extrusions

Extruded Rubber Products

Wepo leaders in rubber extruding Intricate shapes and designs, which have otherwise been difficult to manufacture.

Introduction

Extruded Rubber Products

We Take Pride In Extruding Intricate Shapes And Designs, Which Have Otherwise Been Difficult To Manufacture.

Rubber Extrusions For Every Application Custom Engineered. Precision Built complies all specified technical standards

Wespo maintaining consistent product sizes and quality which meeting customer technical specification and makes wespo Rubber Extrusions

The most Reliable In The Industry.

- 30+ Years Experience

- Design Guidance

- Array Of Products

Why Choose Wespo For Rubber Extrusions

30+ Years of Experience

Design Guidance

Large Range of Products

Extruded Rubber Products

Top Notch Extruded Rubber From Western Polyrub

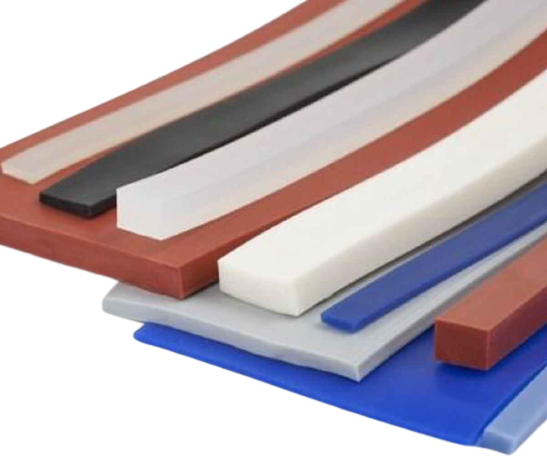

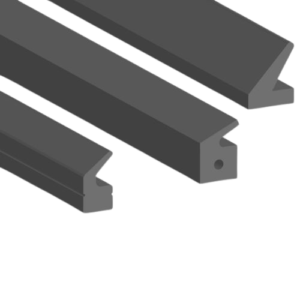

Rubber Extrusions Profile

Manufacturer Of All Types Of Extruded Rubber Seals & Rubber Extrusions. Our Seals Are Made Up Of Elastomers Having Specially Developed In-House Formulations, Which Make Our Seals Not Only Appealing In Aesthetics But Also Long Lasting In Extreme Environments.

'U' SHAPED EXTRUSION

Each industry and application their own requirements for their u channels gasket and u shape rubber seal .wespo understand this fact and can provide taior made u shaped sealing which can meet your needs .

'D' SEAL

Wespo make d seal as per customer application and project requirements d seal can be made in various shapes and sizes using different hardness silicone rubber and color u need.wespo also make transparant and conductive silicone d seal our in house capabilities allows us to offer shorter lead time .

'P' EXTRUDED SEAL

Wespo make p seal as per customer application and project requirements we supply customized p shaped rubber seal and gasket

'H' SEAL

Wespo make H shaped gaskets and seals as per customer requirements additionally u can choose shape ,rubber and pigments as per your projects for more detail contact wespo sales team

'E' SEAL

E type seals are also known as refrigerator seals. These seals have an added benefit of hollow bulbs.

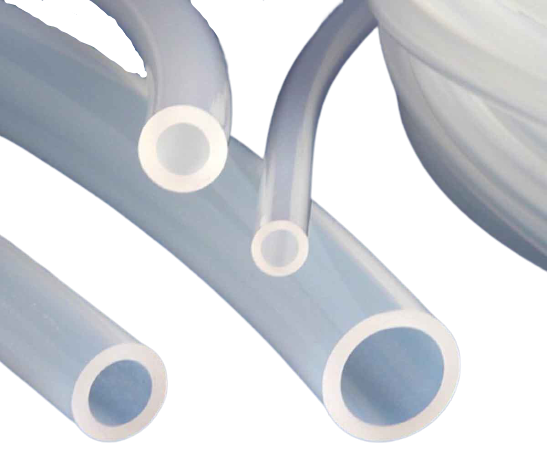

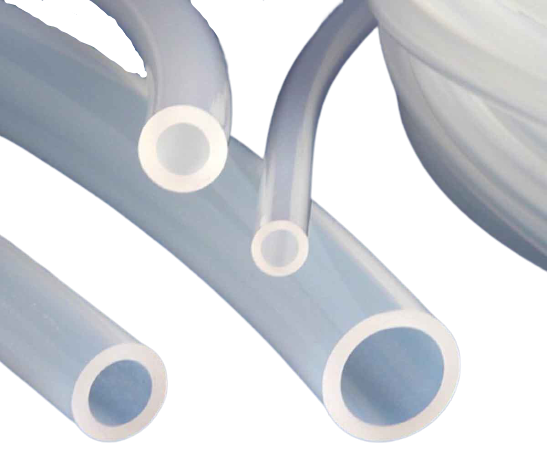

RUBBER CORD

Wespo silicone cord are the perfect products for use in variety of high temp.sealing applications.the cord is avl from 1 mm to 100 mm dia in ur require hardness and colours to suit your specifications.our silicone cord is fully FDA 177.2600 compliant as well as meet EC 1935/2004 std.

FAQ’s

Your Questions Our Answers

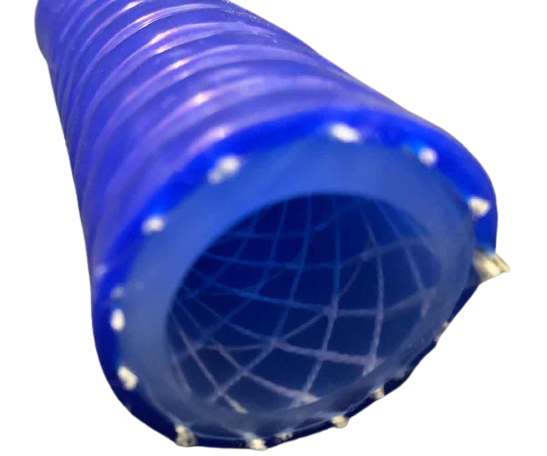

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.