HomeInflatable Seals

Inflatable Seals

Fully Molded Construction of the seal ensure a reliable and effective performance even when the two faces are misaligned or not perfectly aligned , saving time and cost of user this feature makes wespo The Most dependable seal in he Industry.

Introduction

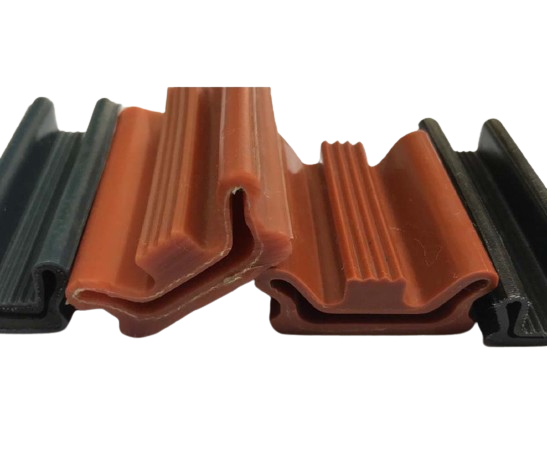

Inflatable Seals Profile

Fully Molded Construction And Fabric Reinforcement Makes Our Inflatable Seals The Most Reliable In The Industry.

100% Leak Proof Inflatable Seals For Every Application Custom Engineered. Precision Built.

Wespo 250 + large selection of Inflatable Seals in stock enable us to offer fast delivery.and we also produce custom and bespoke profiles, designed and mfg,to meet your unique requirements

Wespo 500+ ready Inflatable Seals Profile

- 30+ Years Experience

- Design Guidance

- Array Of Products

Why Choose Us For Inflatable Seals

30+ Years Experience

Large Range Of Products

Design guidance for customized seals

Inflatable Seals Classification

Fully Molded Construction And Fabric Reinforcement Makes Our.

Inflatable Seals

Wespo Inflatable door seal is elastomeric tube or with reinforced (depend on pressure) custom molded in a round concave, convoluted or flat configuration . it is designed to round out with the introduction of an inflation medium to form a tight barrier between a mounting and striking surface.

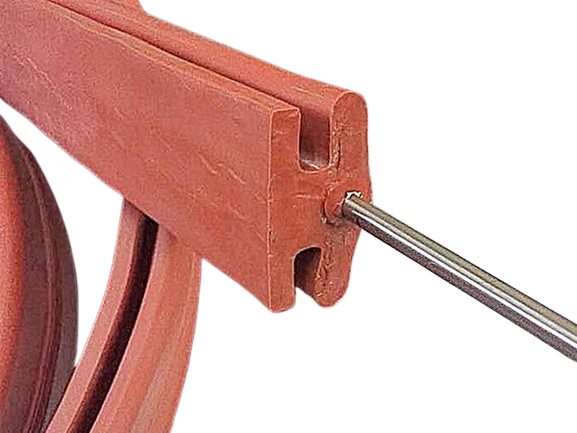

Fabric Reinforced Inflatable Seal

A fabric reinforced seal is a completely molded seal which is built around the same operating principles as a homogeneous inflatable seal. The addition of fabric helps increase the amount of internal pressure by which the seal can operate, where higher pressures are required in a non-enclosed form.

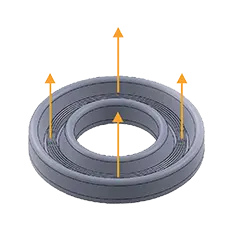

Axial

Axially expanding Inflatable Seals have the centerline diameter as the fixed dimension. The Inflatable Seal expands in the perpendicular direction with respect to the diameter. These seals are sometimes also referred to as face seals.

Radial-Outward

Seals expanding radially outward have the Air Inlet Valves(AIV) typically installed into a channel with the inside diameter (ID) as the fixed dimension.

Radial-Inward

Inflatable seals with small outside diameters may end up wrinkling with this kind of expansion. Seals expanding radially inward have Air Inlet Valves(AIV) typically installed into a channel with the outside diameter (OD).

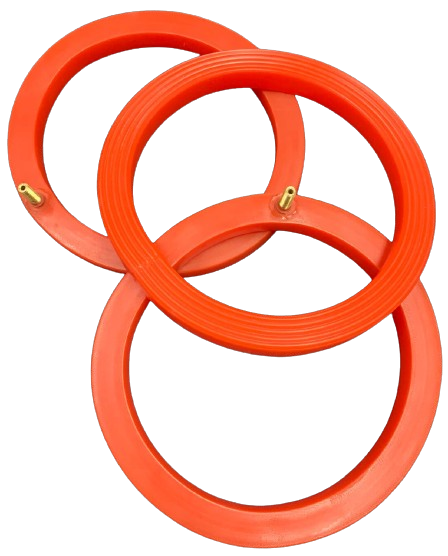

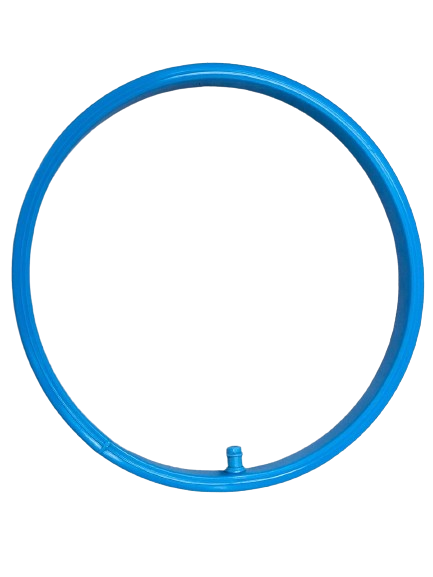

Circular

Inflatable Seals with circular geometry are the most commonly used seals owing to their wide application. Circular Inflatable Seals are the mostly preferred in manhole covers, hopper seals or in industrial machinery like fluidized bed dryers, autoclaves; where in the machines are made in circular dimensions.

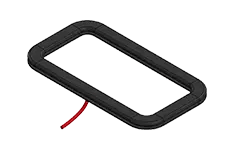

Rectangle

Rectangular Inflatable Seals are very commonly found in door applications like doors for clean rooms, nuclear facility, satellite testing facility, etc. Please note, Western Rubbers’ does not fabricate rectangular seals with tight radiused corners. This is to ensure the seal expansion is not compromised at any point.

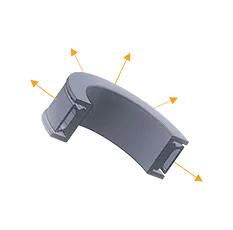

U Shaped

U shaped Inflatable Seals are a common configuration in inflatable gate seals. Ends of u-shaped seals are vulcanized and hence cannot inflate. The uninflated portion of the seal depends upon the seal profile and application. Appropriate retention mechanisms for this configuration is available at Western Rubbers.

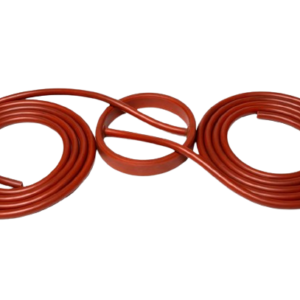

Strip

Inflatable seals with straight configurations are most commonly found in clamps and actuators. Straight seals have vulcanized ends that do not expand. The amount of uninflated area in straight seals depends on profile and application. We provide retention mechanisms that work well for straight seals.

WESPO AIR SEALTM

Wide Range of Inflatable Seals From Wespo

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.