HomeO’Ring Kits & Chord...

O-Rings Standard Sizing

Leading Manufacturer and Exporter of O rings and splicing chord Kits across world.

Introduction

O Ring Kits

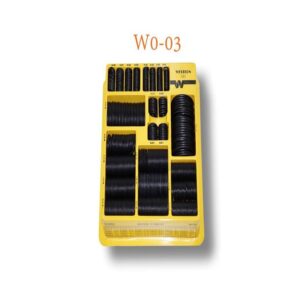

Wespo make o rings used in Compressors ,Pumps ,Valves, Engines, Boilers, and Condensers and many other field .o ring kits WO series 01,02 and 03and splicing chords kit WS series Ws-01 Kit No. Ws-02 Kit No. Ws-03

Established in 1970 wespo has wide range off the standard 10000 plus o rings for fast shiping and also new sizes are developed as per customer requirements

Wespo o rings meet all standards

- 30+ Years Experience

- Design Guidance

- Array Of Products

Products Benefits

Thermally Conductive

We use latest technology for rubber mixing, adhesive chemistry and bonding process.

Anti-Wear Design

We use latest technology for rubber mixing, adhesive chemistry and bonding process

Durable Quality

We use latest technology for rubber mixing, adhesive chemistry and bonding process.

O Ring Kits Standard Sizing

Fully Molded Construction And Fabric Reinforcement Makes Our.

Hollow Orings

Hollow orings are an alternative to standard o-rings, when low closing force is required. The reduced closing force is achieved by replacing the solid cross-section by a hollow cross-section, without reducing the material hardness. Hollow o-rings are used for instance for sealing lids and doors.

O-Ring and L Ring For OTR tyre

Wespo makes and export o rings and l rings for OTR tire including rim sizes 20 to 51 inches ,o rings are made from EPDM and NATURAL rubber as per requirements wespo o rings retain its orignal shape resisting pressure and thermal fluctuations in wheel groove

Western Chord Kit No. Ws-01

7 Different Sizes Rubber Chords: 2 meters each (1.6mm, 2.4mm, 3.2mm, 4.8mm, 5.7mm, 6.4mm, & 8.4mm)

Western Cord Kit No. Ws-02

10 Different Sizes Rubber Cords- 1 Mtr. Each (1Mm, 2Mm, 3Mm, 4Mm, 5Mm, 6Mm, 7Mm, 8Mm, 9Mm, 10Mm)

Western Cord Kit No. Ws-03

Rubber Cords- 10 Different Sizes Rubber Cords- 1 Mtr. Each (1Mm, 2Mm, 3Mm, 4Mm, 5Mm, 6Mm, 7Mm, 8Mm, 9Mm, 10Mm)

AS-568 O-RING

Major O-ring manufacturers follow the AS568B standard for maintaining standard sizes in their inventory. These sizes in Aerospace Standard (AS568B) given by the Society of Automotive Engineers are defined by dash numbers. Each dash number corresponds to a fixed size.

BS-1806 O-RING

British Standard or BS standard includes all sizes in AS568 with some other additions. BS 1806 O ring size standard was issued by British Standard Institution and has a list of all Imperial size standards. Though this has been superseded by BS ISO 3601, it is still relevant in today’s time as it is widely referenced in the European region.

JISB-2401 O-RING

The Japanese Industrial Standard ( JIS B2401) are categorized in to 3 groups, namely, Aerospace Group, General Purpose Group and Traditional Group. These O rings are used in Japans’s Automotive, semi-conductor, heavy engineering and other allied industries. The JIS B2401 follow ISO 3601-1 very closely with a few extra sizes.

METRIC O-RING

Standard metric sizes for O-rings are defined by the International Standard ISO 3601-1:2002: Fluid power systems O-rings Part 1. These sizes are grouped into 2 series; G and A. G series is preferred for general applications and A series is recommended for Aerospace or any other critical application requiring sharp tolerances.

PTFE O-RINGS

PTFE encapsulated O-rings, also known as FEP encapsulated and PFA encapsulated o-rings, are Vitoria or Silicone O-rings encapsulated within a PTFE jacket These o-rings hence offer an ideal combination of the unique properties of vitons/siiicone as well as PTFE. They outperform the conventional o-rings in harsh environments owing to their excellent chemical resistance, temperature resistance and mechanical properties. Depending on the core material i.e. Viton° or Silicone, they are suited for operating in temperatures ranging from -62° to 204°C (-80° to +400° F)

X-RINGS

X-Rings, also known as quad rings, are a hybrid design of an O ring and a square ring. Compared to o-rings, which have a single lobed design, x-rings come with a four-lobed design. X-rings offer twice the sealing surface in comparison to a standard o-ring. Due to this double sealing function, x-rings provide a double sealing function and can be used in a variety of static as well as dynamic sealing applications. The double-seal action requires less squeeze to maintain an effective seal. This reduction in squeeze in turn means less friction and improved seal life.

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.