HomeFlexible Bellows & Connect...

Flexible Bellows & Flexible Connector

Flexible bellows and connectors are essential components used in various industries for applications such as vibration isolation ,thermal expansion compensation and fluid or gas transfer.

Introduction

Best Place To Buy Flexible Bellows & Connector

Rubber bellow, connector and expansion Joints Are Flexible Fabricated From Natural Or Synthetic Elastomers either Fabrics With Metallic or non metalic Reinforcements Designed To Provide Stress Relief In Piping Systems Due To Thermal Changes.and also to pass fluid,powder or any other material

FDA and EURO approved bellow and connector for pharma,medical,powder,and food industries .

wespo rubber bellow is flexible cover to protect machine against dust,oil,grease,acides and other elements ,flexible connector is used for adjoining spouts on hoppers,mixers,silos,and more

Fully moulded wespo brand more then 500 plus flexible bellow and connector.

- 30+ Years Experience

- Design Guidance

- Array Of Products

Product Benefits

Vibration, Noise, Shock, Corrosion, Abrasion

Stresses, Load Stress, Equipment Movement

Vibration, Pressure & Movement In A Piping

Flexible Bellows and Connector

Best Place To Buy Flexible Bellows and Connector

Depanner Cups And Bellow

Western depanner bellow are constructed From transparent or colored food grade high strength silicone rubber . This Silicone Suction Cups also known as Bellow are extensively Utilized in the Baking Industry .

Flexible Step Bellow

Western One Piece Molded Step Bellows Are For The Flexible Connection Of Mixers, Feeders Or Vessels On Weighing Cells To Supply Lines, Drain Pipes Or Other Forms Of Air Transport Or Powder Transport With 2 Different Dimension Tubing.

Gravimetric Feeder Bellow

Weighing Bellow Round And Conical Fda And Ecc Approved Western Silicone Weighing Round Bellow Is A Molded Flexible Connection In Transparent Fda Silicone Rubber (Also Available In Black Conductive Silicone Rubber). This Silicone Bellow Is Very Flexible And Thin And It Is Specially Designed For The Use In Weight Systems

Vibro Sifter Sleeves

Western Mold Sifter Sleeve In Fda And Ecc Approved Material With Groove In Inside Dia Which Corresponds To Bead Ring Of The Inlets And Outlets. Corrugated Sleeves Are The Heart Of Flexible Connections

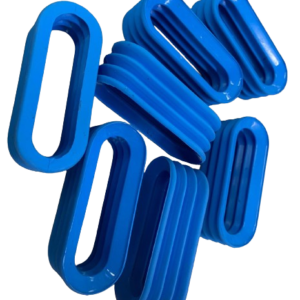

Silicone Connector

Wespo Branded Silicone Connector Sleeves Can Be Used For Various Low And High Pressure Applications Such As Duct Misalignment, Anti-vibration Couplings , Fluid Or Powder Transfer And Silo Outlets.

Silicone Rubber Bellow

Wespo Connect Silicone Bellow Is Used To Protect Lead Screws / Precision Shafts / Moving Cylinders / Irregular Shaped Parts,Transfer Liquid Or Solid ,Flexible Connection And Many Fda Applications

Silicone Weighing Bellow Round

Wespo round Weighing Bellow Is A Molded Round Flexible Connection. available In Transparent Fda And Ecc Approved Silicone Rubber (Also Available In Black Conductive Silicone Rubber For Atx Zone).

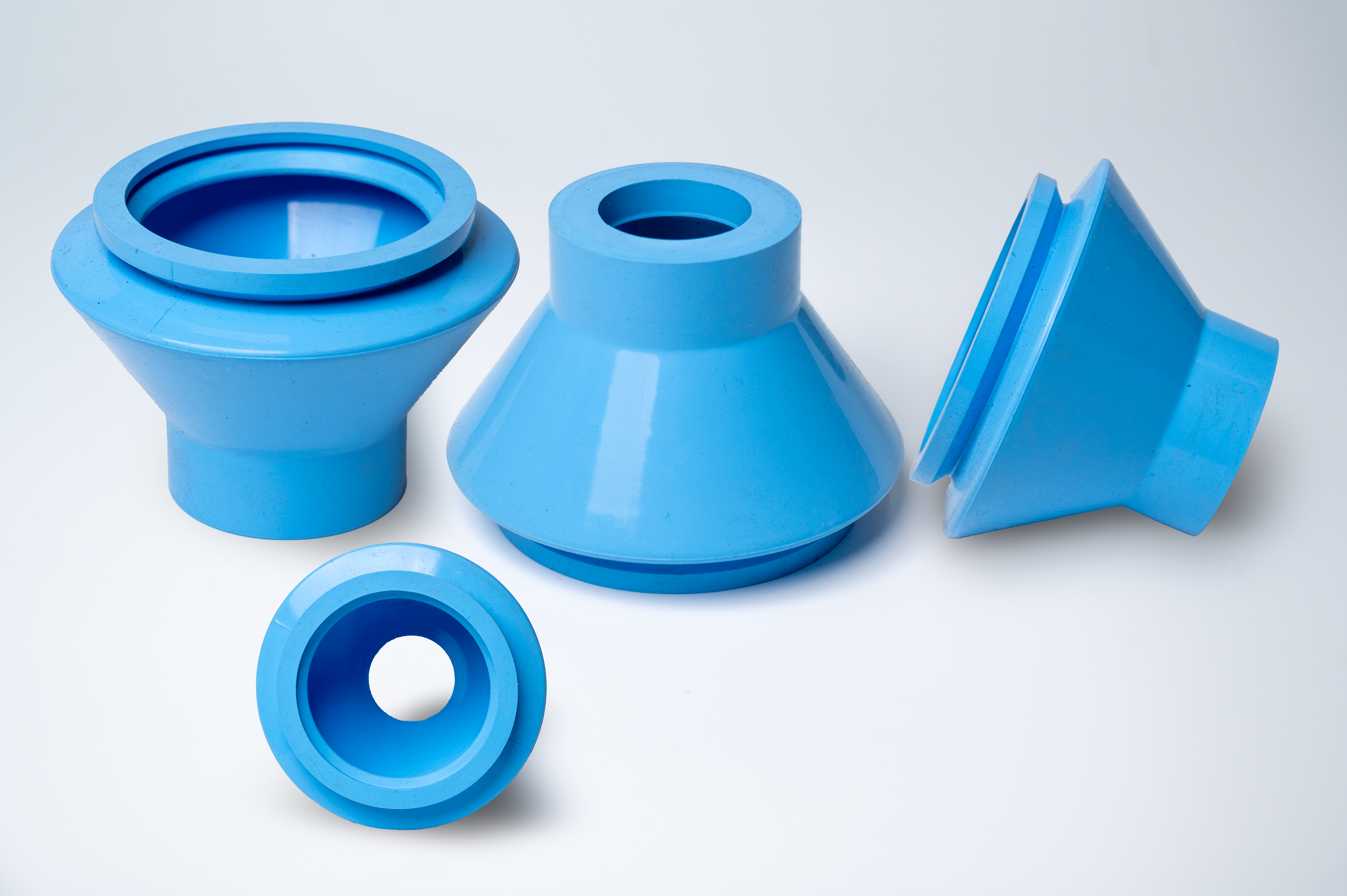

Silicone Weighing Bellow Conical

Wespo Conical Weighing Bellow available In Transparent Fda And Ecc Approved Silicone Rubber (Also Available In Black Conductive Silicone Rubber For Atx Zone). Weighing Bellow Is Very Flexible And Thin And It Is Specially Designed For The Use In Weight Systems.

Conductive Silicone Weighing Bellow

Wespo Conductive Silicone Weighing Bellow Comes In Black Colour Made From Food Grade Silicone Rubber Mixed With Conductive Carbon To Make The Silicone Compound Conductive And Resist Lower Than <10^6 Ohm.

Suction Cup

Wespo suction cup is a sort of instrument used in a vacuum system to grip and move objects for pick-and-place applications.

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.