HomeConductive Molded & Extrud...

Conductive Molded & Extruded Rubber Parts

Common profile configurations of Conductive Elastomers are: “D”, Round, “P”, Square, and Rectangular.

Introduction

Best Place To Buy Conductive Molded & Extruded Rubber Parts

Conductive Rubber is made from Conductive carbon or other conductive filler which can be die-cut to form a flat gasket or washer but one of the large differences from other materials is that Conductive rubber also be provided in a variety of different extruded profiles. wespo also mfg.conductive rubber with flame retardent and high temprature withstand

Wespo Molded & etxtruded conductive Rubber Parts For electrical and many others Application

Common profile configurations of Conductive Elastomers are: “D”, Round, “P”, Square,tube and Rectangular; these profiles can be extruded as a solid cross section or hollow depending on the compression required and height.

Wespo designed electrically conductive silicone rubber parts is perfectly suited to provide superior shielding from radio frequency and electromagnetic interference. Acting as a low amperage conductor, these moulded and extruded parts will also give you far greater protection against electrostatic discharge, with the addition of also being flame-retardant.

Products Benefits

Vibration, Noise, Shock, Corrosion, Abrasion

Stresses, Load Stress, Equipment Movement

Vibration, Pressure & Movement In A Piping

Conductive Molded & Extruded Rubber Parts

Molded Rubber Parts Made Specifically For Your Business.

Antistatic Inflatable Seal For Fluid Bed Dryer

Pharmaceuticals utilize volatile solvents that can ignite when exposed to a spark due to static discharge ,which may cause damage to the material and potential harm to person during working in the area the use of wespo inflatable seal prevents material from damage due to spark.

Antistatic Bellow For Sifter

Western polyrub has developed corrugated flexible bellow for sifter in FDA and euro approved wsds ( western static dissipative silicone ) rubber. In grey or white colour with all certification.

Conductive Silicone Sheet

Wespo Electrically Conductive Silicone Sheet is a high strength special grade silicone material that gives you the right balance between electrical conductivity ( low amperage conductor) + protection against electrostatic discharge & material cost.

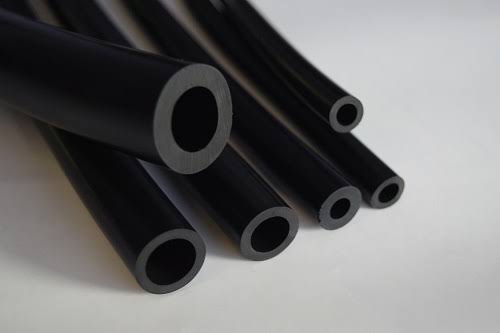

Conductive Silicone Tubing

Western Electrical Conductive Silicone Tubing (Which Is Not Food Grade )Used To Help In Minimising Or Remove Static Discharge Build Up And Save Products From Fire Or Damage

Antistatic Silicone Gasket For Sifter Sieves

WSDS (western static dissipative silicone ) branded sieve gasket are commonly used for sealing around the outside of sieves in powder transfer applications.

Antistatic Silicone Sieves

Wsds (Wespo Static Dissipative Silicone Sieves Are Technologically Leading In Their Innovative Designing As They Are Exceptionally In Complex In The Way Of Their Usage.

Antistatic Silicone Rubber Tube

Wsds (Wespo Static Dissipative Silicone Sieves Are Technologically Leading In Their Innovative Designing As They Are Exceptionally In Complex In The Way Of Their Usage.The Superf Luous, Likely Corruptive, Rivets & Tails Are Totally Obliterated The Unrequired Clips Are Eliminated.

Silicone Moulded Dutch Sieves For Fbd

Wespo make FBD sieves from 300 to 1200 mm dia also called 25 ltr to 1000 ltr capacity .wespo sieves are used as dutch woven screen .the most common sieve used is 24 x 110 and 30 x 150 mesh

Flexible Bellows & Connector

Top Notch Slicone Bellow From West Polyrub

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.