HomeProductsMolded Rubber ProductsRubber Diaphragm

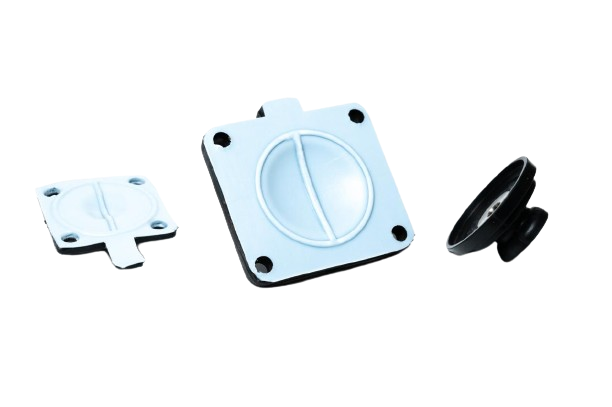

Rubber Diaphragm

Wespo specializes in manufacturing custom engineered rubber diaphragm using top quality polymer and fabric

Rubber Diaphragm

Fabric reinforced rubber diaphragm are our expertise from last 30 + years.

Wespo are manufacturers and exporters of rubber diaphragms with various materials and bonding option offering a range of diaphragms in natural and synthetic rubber with or without fabrics reinforced as well as different bonding options such as metal ,plastic , carbon or ptfe ,gives our customers a variety of choices to suit their specific needs and applications providing such versatility can help to cater wider range of industries

Wespo diaphragm range:

Wespo’s range of diaphragms includes plain, concave, convex, saunders type, cup type, hat type & saucer type, with or without fabric reinforcement.

How to identify the right elastomers for the Wespo diaphragm?

The diaphragm comprises different elastomers, each designed to perform best under certain conditions. There are three primary data points you need to identify to determine which elastomer to select for a given application:

1 operating temperature

2 levels of potential corrosion

3 levels of potential wear

The following factors are important in choosing the right fabric

1 diaphragm stroke rate effect

2 risk of tearing of the fabric due to flange sealing conditions

3 required balance between sensitivity and strength of the fabric

4 environmental impact on the fabric, i.E. Flammability, and temperature

Types of diaphragms:

Valve diaphragm

Pump diaphragm

Actuator diaphragms

Wespo saunders rubber and ptfe diaphragm size range

XE and XB a type: DN08 – DN350

XC a type: DN015 – DN350

XF a type: DN65

KB Type: DN015- DN350

Wespo flat Rubber Diaphragm

Flat Rubber Diaphragms are molded from tools or cut from fabric-reinforced sheet wespo flat diaphragms are pressure loadable on both sides.

They have the same effective area on both sides. The flat rubber diaphragms are used for pumps, regulation, control, and measurement.

why choose Wespo rubber diaphragms?

1. One-stop service from compound to manufacture

2. In-house well-equipped mold design and building capabilities

3. Rubber compound tested before production

4. Rubber compounds can be rich, reachable, and FDA-approved. Other certificates can be done according to different customer’s demands

5. Keep secret to your idea and your design.

6. Professional design team, mold maker engineer. Oem/ODM service.

7. Prompt delivery. For prototype: 3- 10 days, production orders can be arranged specially to meet customer’s urgent demands

8. Professional QC and R&D teams to ensure high quality of all diaphragms duly marked with mfg date and year

Wespo studies diaphragm performance in three important ways.

1) short-term, room temperature burst testing:-

we study the burst pressure over several orifice sizes to determine the strength of the material and project the burst pressure in commercial regulators

2) temperature de-rating burst testing:-

we study the degradation of burst strength of the material at various elevated temperatures to roughly estimate a temperature derating factor. Our internal data is compared with published data where available.

3) Performance Testing:-

we run performance trials with various diaphragm materials to know where best to apply them. This includes determining the lowest flow achievable with any particular material.

We have spare diaphragm quality similar to bellow or valve manufacturer :

1 Samson control

2. Ghatge Patil Industries Ltd

3. Valve works USA

4. Forbes Marshall

5. Hora valves

6. Technic Valves Pvt Ltd

7. John crane valve

8. Fisher valve

Wespo rolling rubber diaphragms

Are special diaphragms shaped like top hats that provide the properties of both bellows and diaphragms?

The rolling diaphragms have deep folding parts, which allow smooth rolling action.

A long stroke is possible, and the effective pressure-receiving area will be maintained the same throughout the operation.

Because the rolling rubber diaphragm will move with a rolling action, it will not be necessary to pay special attention to the surface finish, materials, and hardness of the piston and the cylinder.

In addition, these rolling rubber diaphragms can respond to minute pressure variations, greatly contributing to improving the performance of equipment in the air pressure and liquid pressure control fields.

The design of the rolling rubber diaphragms enables their use without any lubrication. The rolling action of this type of diaphragm allows no friction loss in addition to extremely small hysteresis loss.

When using rolling rubber diaphragms there is no leakage(very low levels to be exact, however, there will be a tiny permeation through the rubber membrane.). The effective pressure-receiving area will constantly stay the same throughout the full stroke.

Because the folding parts of the rolling rubber diaphragms are narrow, they can be designed for extremely low-pressure (250pa) applications to high-pressure (9.81mpa) applications.

The rolling rubber diaphragms have a long lifetime due to the rolling action. Rolling rubber diaphragms have a design with an automatic centripetal action. (if the piston is pushed in one particular direction, the pressure will cause a restoring force that will act to return the piston to the center line.)

Wespo diaphragms without fabric

in very low-pressure applications, the strength seen in fabric-reinforced diaphragm may not be necessary. For these special applications, western offers diaphragms made with only rubber construction. These diaphragms offer the same functional advantages seen in fabric-reinforced diaphragms, but they have the added economy of using the special construction is possible using all types of elastomers as per technical specifications

Main causes of failure of the diaphragm

To avoid overlapping of fabric and ensure a smooth diaphragm shape, molding the fabric first to fit the desired shape without any wrinkles is a great approach. bonding the fabric with rubber in the mold and applying heat can achieving the required shape and ensuring a strong bond between the materials. This process can help prevent diaphragm failure and ensure quality and products.

WESPO MATERIAL DATA SHEET

![]()

leading manufacturers of fabric inflatable seal

Today western polyrub stand out as leading manufacturers of fabric inflatable seal who make seals with hand built and fully moulded with fabric reinforcement inside make seal so tough that can withstand pressure up to 50 Kgcm2 Fabric Reinforced Rubber Seals Are Effective Where Moderate- To High-pressure Is Applied(we make seal up to 50bar bursting pressure ) , Such As In Heavy Industrial, Environmental, Technical And Laboratory Environments,marine,nuclear Region A Variety Of Reinforcing Fabrics Are Available And Determined By Factors Such As Temperature And Pressure.

Fabric inflatable seal moulded

Wespo also provide fabric inflatable seal moulded with rubber nozzle for flexibility and longer life if clients demand Western Polyrub Offers Technical Guidance To Determine The Appropriate Design, Manufacturing And Material Composition. The Fabric Inflatable Must Withstand Environmental Factors And Perform Using Air Or Gas Controlled Mechanisms Under Pressure. The Environment And Structure Will Affect The Choice

OFFSHORE APPLICATION

Western polyrub has developed technology to used fabric reinforced inflatable seal in a number of critical applications including offshore production, storage and offloading (FPSO); anchoring drill rigs to the seabed; gas loading systems; pipeline welding; and watertight doors and panel High -pressure inflatable seals are designed to fit in metal retaining grooves, allowing axial, external radial and internal radial expansion, These seals typically can withstand pressures of up to 8 bar, and are suitable for sealing clearances from 2-10mm.

Applications Of Rubber Diaphragm

- Typical applications for wespo diaphragms (like pumps and valves) are in process control.

- Water management

- Food and beverages processing

- Gas regulators

- And other industrial systems

- Aerospace

- Industrial, Electronic, Agricultural, Chemical and Medical Products

Features

- Diaphragm Material -

- EPDM

- NBR

- SILICONE

- PTFE

- VITON®.

- Nitrile (Buna N)

- POLYURETHENE

- NEOPRENE

- Features -Positive Seal, Diffrent grade of fabric, Low Spring Rate, No Lubrication,No Breakaway,Force No Friction High Strength Functionality, Over Wide Pressure Ranges, Competitive, Easy Design

SKETCH DRAWING

Send your sketch or drawing

MATERIAL

Choose the Material

SPECIAL FEATURE

Add the special feature

FINAL PRODUCT

We will deliver your product quickly.