HomeProductsMolded Rubber ProductsRubber O Rings

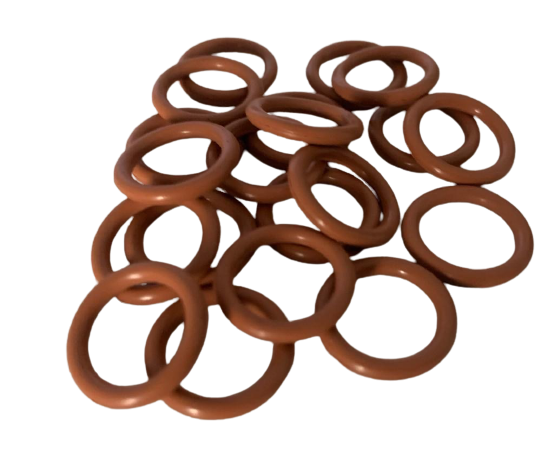

Rubber O Rings

Wespo offers rubber O rings in variety of standard compounds to meet different application needs .The range of compounds wespo provide such as :FFKM,PTFE,XNBR,PU,SPONGE,METAL DETECTABLE ,CONDUCTIVE ,AFLAS and HNBR indicates a diverse selection to cater to specific requirements like high temperature resistance ,chemical compatibility ,conductivity and more these different materials have unique properties that make them suitable for various ind.applications

Rubber O Rings

Wespo offering custom rubber O rings solutions tailored to specific customer requirements Whether it is single moulded or spliced from cord and vulcanised with adhesive they seems to provide flexibility based on the application needs.custom o rings can be crucial for ensuring a proper seal in various industrial applications .

Wespo make all international standard rubber o rings:

a ) AS-568 O-ring

major o-ring manufacturers follow the as568b standard for maintaining standard sizes in their inventory. These sizes in aerospace standard (as568b) given by the society of automotive engineers are defined by dash numbers. Each dash number corresponds to a fixed size.

b ) BS-1806 O-ring

British standard or bs standard includes all sizes in as568 with some other additions. Bs 1806 o ring size standard was issued by british standard institution and has a list of all imperial size standards. Though this has been superseded by bs iso 3601, it is still relevant in today’s time as it is widely referenced in the european region

c ) JISB-2401 O-ring

the japanese industrial standard ( jis b2401) are categorized in to 3 groups, namely, aerospace group, general purpose group and traditional group. These o rings are used in japans’s automotive, semi-conductor, heavy engineering and other allied industries. The jis b2401 follow iso 3601-1 very closely with a few extra sizes.

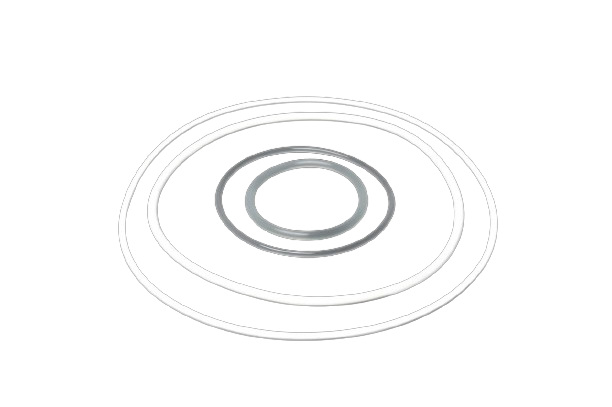

d ) Metric O-ring

standard metric sizes for o-rings are defined by the international standard iso 3601-1:2002: fluid power systems o-rings part 1. These sizes are grouped into 2 series; g and a. G series is preferred for general applications and a series is recommended for aerospace or any other critical application requiring sharp tolerances

PTFE O-rings

ptfe encapsulated o-rings, also known as fep encapsulated and pfa encapsulated o-rings, are vitoria or silicone o-rings encapsulated within a ptfe jacket these o-rings hence offer an ideal combination of the unique properties of vitons/siiicone as well as ptfe. They outperform the conventional o-rings in harsh environments owing to their excellent chemical resistance, temperature resistance and mechanical properties. Depending on the core material i.E. Viton° or silicone, they are suited for operating in temperatures ranging from -62° to 204°c (-80° to +400° f)

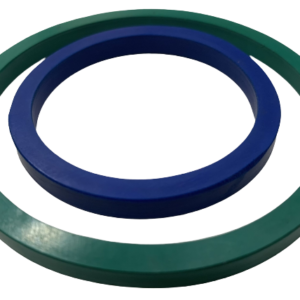

X-Rings

X-rings, also known as quad rings, are a hybrid design of an o ring and a square ring. Compared to o-rings, which have a single lobed design, x-rings come with a four-lobed design. X-rings offer twice the sealing surface in comparison to a standard o-ring. Due to this double sealing function, x-rings provide a double sealing function and can be used in a variety of static as well as dynamic sealing applications. The double-seal action requires less squeeze to maintain an effective seal. This reduction in squeeze in turn means less friction and improved seal life.

DOWNLOAD WESPO DATA SHEET:

- VITON HARDNESS 70A

- SILICONE HARDNESS 70 A

- NBR HARDNESS 70 A

- EPDM HARDNESS 70A

- WESPO RUBBER TECHNICAL DATA SHEET

![]()

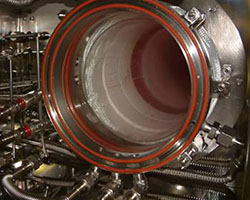

leading manufacturers of fabric inflatable seal

Today western polyrub stand out as leading manufacturers of fabric inflatable seal who make seals with hand built and fully moulded with fabric reinforcement inside make seal so tough that can withstand pressure up to 50 Kgcm2 Fabric Reinforced Rubber Seals Are Effective Where Moderate- To High-pressure Is Applied(we make seal up to 50bar bursting pressure ) , Such As In Heavy Industrial, Environmental, Technical And Laboratory Environments,marine,nuclear Region A Variety Of Reinforcing Fabrics Are Available And Determined By Factors Such As Temperature And Pressure.

Fabric inflatable seal moulded

Wespo also provide fabric inflatable seal moulded with rubber nozzle for flexibility and longer life if clients demand Western Polyrub Offers Technical Guidance To Determine The Appropriate Design, Manufacturing And Material Composition. The Fabric Inflatable Must Withstand Environmental Factors And Perform Using Air Or Gas Controlled Mechanisms Under Pressure. The Environment And Structure Will Affect The Choice

OFFSHORE APPLICATION

Western polyrub has developed technology to used fabric reinforced inflatable seal in a number of critical applications including offshore production, storage and offloading (FPSO); anchoring drill rigs to the seabed; gas loading systems; pipeline welding; and watertight doors and panel High -pressure inflatable seals are designed to fit in metal retaining grooves, allowing axial, external radial and internal radial expansion, These seals typically can withstand pressures of up to 8 bar, and are suitable for sealing clearances from 2-10mm.

Applications Of Silicone Flange Gasket

- General purpose for machine shop, Plumbing , Engineering Maintenance.

- Available Standard : JISB 2401, AS-568, BS 4518,GB-T3452.1,JISB 2401, Swedish SMS 1586, Din, Sae ,Metric and specifics for Automotive , High precision for medical and watch case and heavy duty machine specifications.

Features (Materials)

- Nitrile (Nbr)

- Hydrogonated Nitrile (hnbr)

- EPDM

- Neoprene

- Silicone

- Fluoroelastomer (fpm)

- PTFE

- And in FKM,Aflas,Viton extreme 50/90 shore hardness

SKETCH DRAWING

Send your sketch or drawing

MATERIAL

Choose the Material

SPECIAL FEATURE

Add the special feature

FINAL PRODUCT

We will deliver your product quickly.