HomeWespo Non Standard Molded Prod...

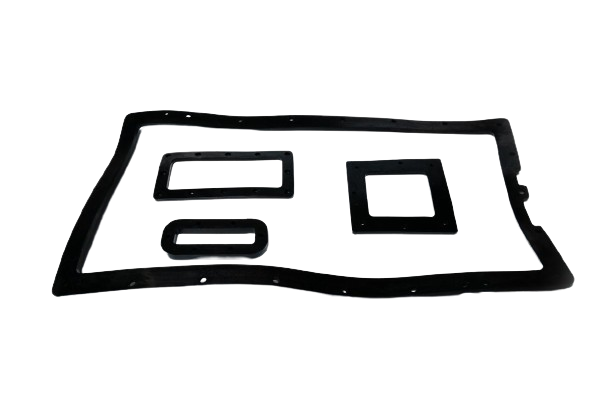

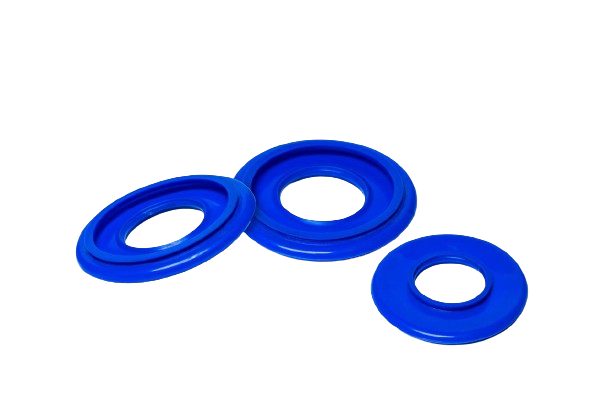

Wespo Non Standard Molded Products

we understand that not all challenges come in standard sizes. That’s why our WESPO range offers tailor-made molded rubber solutions—designed from scratch to meet your unique requirements with precision, durability, and care

When Standard Doesn’t Fit, We Mold It Right

Western Polyrub Offers Custom Engineered Rubber Solutions To Customers Across The Globe.

Aflas Genuine Viton Moulded And Extruded Parts

Western polyrub are manufacturer and exporters of moulded and extruded parts from above new generation polymer.

Rubber Parts For Solar Industry

Solar energy has become increasingly popular as an alternative energy source in recent years. Solar photovoltaic (pv) modules use flat panels, parabolic mirrors, fresnel lenses, and flexible thin-film panels to collect and convert sunlight into electricity. Electricity generated from these sources is then converted from dc to ac for distribution and daily use.

FAQ’s

Your Questions Our Answers

An inflatable seals operates by introducing an inflation medium. Upon introduction of the inflation medium, it quickly expands to the striking surface, affecting a positive seal. When the inflation medium is removed, the seal retracts naturally to the deflated molded configuration. This provides clearance for free movement of one or both surfaces.

An inflatable seals has several advantages over other sealing methods:

• It provides a leak-proof closure, yet allows clearance when needed.

• It simplifies the design of the structure and hardware.

• It minimizes the need for close machining and/or fabricating tolerances.

• It is not subject to a compression set which negates the effectiveness of other seals.

Yes! Essentially all Western Polyrub Inflatable seals are custom rubber seal designs. After over 30-years in business, more than 8000 unique products have been developed. Take a look at all of the unique designs at inflatable seals product category.

It’s important to consider the application’s environment: gas temperature, radiation and abrasion exposure when maintaining your inflatable seal. Learn more about these application environmental considerations.

Generally for nominal pressure applications we suggest customers to avoid fabric-reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.

Generally for nominal pressure applications we suggest customers to avoid fabric reinforced seals so as to avoid high costs. But if your differential pressure requirements are higher than 7-8 Bar then we suggest customers go for fabric.