HomeProductsExtruded Rubber ProductsVIton Sponge Extrusion

VIton Sponge Extrusion

VitON (fkm ) sponge extrusion and sheeting available in a wide range in any thickness in strip ,round or any profile shape

VIton Sponge Extrusion

Wespo fkm sponge extrusion is resistant to corrosive attack from a wide variety of chemicals and fluids. It delivers better protection against oils, fuels, lubricants, most mineral acids and fire resistant hydraulic fluids.

Fkm sponge also performs well in many aliphatic and hydrocarbons that act as degrading solvents for other types of rubbers. Fkm extrusion and sheeting operates over a broad temperature range of -25 to +200 c and resistance to :

Wespo viton sponge extrusion available in many colours and also FDA compliance and metal detectable as per requirements

*Viton is trademark of the chemours company

Acid Resistant Acid Resistant |  Weather Resistant Weather Resistant |

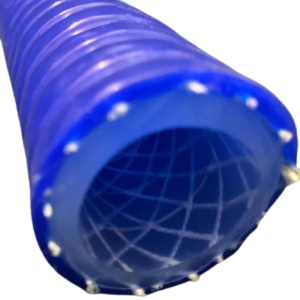

leading manufacturers of fabric inflatable seal

Today western polyrub stand out as leading manufacturers of fabric inflatable seal who make seals with hand built and fully moulded with fabric reinforcement inside make seal so tough that can withstand pressure up to 50 Kgcm2 Fabric Reinforced Rubber Seals Are Effective Where Moderate- To High-pressure Is Applied(we make seal up to 50bar bursting pressure ) , Such As In Heavy Industrial, Environmental, Technical And Laboratory Environments,marine,nuclear Region A Variety Of Reinforcing Fabrics Are Available And Determined By Factors Such As Temperature And Pressure.

Fabric inflatable seal moulded

Wespo also provide fabric inflatable seal moulded with rubber nozzle for flexibility and longer life if clients demand Western Polyrub Offers Technical Guidance To Determine The Appropriate Design, Manufacturing And Material Composition. The Fabric Inflatable Must Withstand Environmental Factors And Perform Using Air Or Gas Controlled Mechanisms Under Pressure. The Environment And Structure Will Affect The Choice

OFFSHORE APPLICATION

Western polyrub has developed technology to used fabric reinforced inflatable seal in a number of critical applications including offshore production, storage and offloading (FPSO); anchoring drill rigs to the seabed; gas loading systems; pipeline welding; and watertight doors and panel High -pressure inflatable seals are designed to fit in metal retaining grooves, allowing axial, external radial and internal radial expansion, These seals typically can withstand pressures of up to 8 bar, and are suitable for sealing clearances from 2-10mm.

Applications Of VIton Sponge Extrusion

- Sealing of engine bays with large, irregular gap lengths with sponge rubber profiles. The high temperatures prevalent there in combination with oils and grease are no problem for sponge FKM. The light deformability of such profiles is recovering quick.

- Applications that require high acoustic damping in conjunction with aggressive chemicals.

- Due to the cellular structure of FKM / Viton sponge rubber, the heat conductivity is heavily reduced. Thus, applications that require high thermal insulation in conjunction with other extreme properties of fluoroelastomers are conceivable.

- Sponge FKM / Viton sheeting can also be applied as soft wiping medium, in order to remove hot oil from rotating metal shafts. The service life is considerably longer than in conventional sponge rubber types.

Features (Wespo also have alternative arrangements) :-

- Durability

- Retention of flexibility

- Corrosive chemical resistance

- Resistance to evaporative permeation

- Extreme temperature resistance

SKETCH DRAWING

Send your sketch or drawing

MATERIAL

Choose the Material

SPECIAL FEATURE

Add the special feature

FINAL PRODUCT

We will deliver your product quickly.