When it comes to maintenance and repairs on your industrial machinery, you need O-rings and seals that are built to last. And you need them fast. After all, you don’t have time to waste on a seemingly endless search for the perfect OEM replacement part. Fortunately, we’ve done the research for you and narrowed down our top picks for o-ring and seal selection depending on the needs of your business. From budget-friendly alternatives to premium options that stand up to the test of time, we’ve got an o-ring or seal for every facet of your operation.

With that in mind, let’s take a look at 5 key points whenever choosing o-rings and seals:

What are O-Rings and Seals?

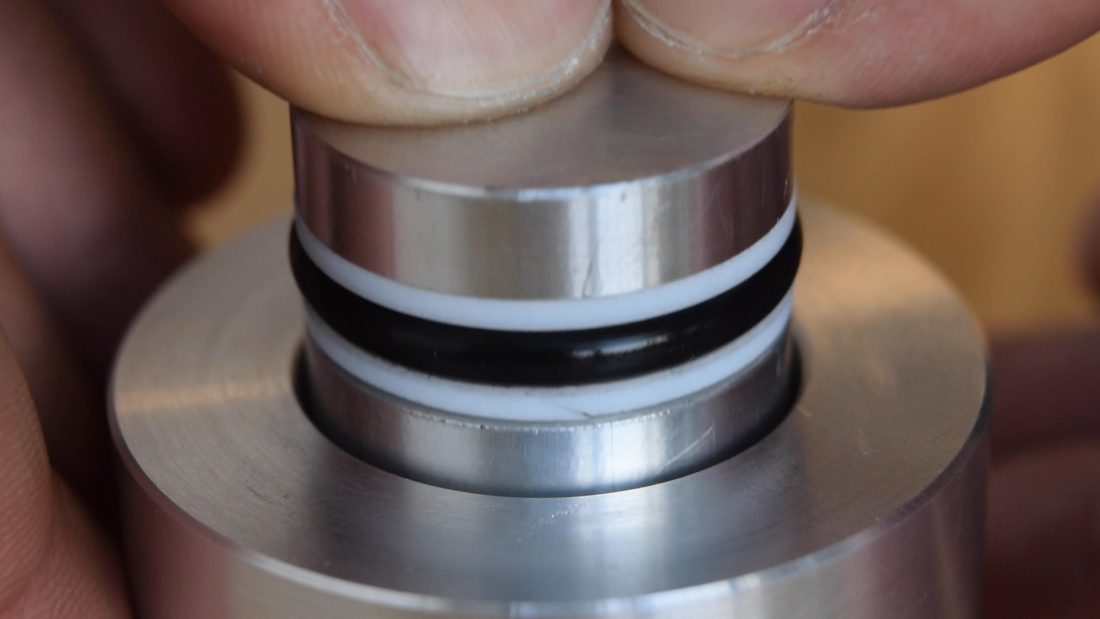

O-rings and seals are two types of rubber products used to create mechanical and environmental connections. While o-rings are also called compression or pressure seals, they are designed to maintain a certain pressure without leaking. You’ve most likely come across them in the form of gaskets, automotive seals, and many other applications. Generally, they are made from synthetic rubber that is either vulcanized or thermoplastic vulcanized.

Here’s what sets them apart from other rubber products:

- They are non-porous, meaning they are non-absorbent. This results in better durability and longer service life under extreme conditions.

- Because they are not porous, they don’t absorb chemicals. This makes them ideal for applications where chemicals may be present.

- They are very flexible but can be pressurized to very high tolerances.

- They are available in a variety of thicknesses and grades to suit various applications. – They are available in a wide range of colours.

Related Topic: How To Increase The Operational Life Of Inflatable Seals

Types of O-Rings and Seals

Sheet: These types of o-rings are generally made from rubber sheets or sheets of high-density rubber. They are available in either a roll or sheet cut to size.

Doughnut-Shaped: These are generally made from high-density rubber, and are used in sealing applications that need to be pressurized to very high tolerances.

Low-Pressure: The low-pressure o-rings are generally made from silicone. They provide good pressure resistance and are commonly used for seal applications where high temperatures are not expected.

High-Pressure: The high-pressure o-rings are generally made from synthetic rubber. They are often used in extreme conditions where pressure is required.

How to Select the Right O-Rings and Seals for Your Application

- Each type of o-ring has different properties and will be best suited to certain applications. Make sure to research and compare the different o-ring and seal types available to find the perfect fit for your needs.

- The first thing you need to do is determine the application for which you want to use the o-rings and seals. This is essential to finding the best fit for your requirements. For instance, you may want to use them for sealing a container that is going to be exposed to high temperatures or chemicals, or a high-pressure application where pressure resistance is required. – Next, research the different types of o-rings and seals available. If you don’t know where to start, then take a look at our comprehensive o-ring and seal review above for more information.

- Once you’ve narrowed down your options to a few types, then start comparing their performance and cost. You can make use of various tools and resources available online to compare o-ring and seal types, as well as their prices, performance ratings, and other relevant information.

- You may also want to conduct a trial run to see if the o-rings and seals perform as expected before committing to the purchase. This way, you can ensure that they will be suitable for your needs.

- Last but not least, make sure to perform due diligence on the o-ring and seal vendor before making a purchase. Make sure to check the credentials of the seller and make sure that they are authentic, reliable, and legitimate.

- Factors to Consider When Selecting O-Rings and Seals

Material – The material from which the o-ring and seal are made is an important factor to consider. You want to make sure that the material is suitable for the application, as well as the environment in which it will be used. For instance, a low-pressure silicone o-ring in a high-temperature environment may not be durable enough.

Diameter – The next factor to consider is the diameter of the o-ring or seal. You may want to use a smaller diameter to balance the pressure, or to maintain the pressure of the application while preventing leakage. A smaller diameter may also require less force to maintain the same pressure as a thicker o-ring.

Thickness – When looking at the design of the o-ring, you may want to consider the thickness of the o-ring as well. A thinner o-ring may be more suitable for applications where high pressures are required, while a thicker o-ring may be better suited for a lower-pressure application.

Grades – The final factor to consider when choosing the right o-ring or seal is the grade of the material. There is a wide range of o-ring grades that may be better suited for different applications.

Conclusion

Choosing the right o-ring and seal for your application doesn’t have to be a daunting task. With the right research and knowledge, it can be easily accomplished.

To ensure that you select the right o-ring and seal, you need to make sure that you take the appropriate factors into consideration, including the material, diameter, thickness, and grade of the O-ring and seal.

Find A Reliable Sealing Solution

Wespo can fulfil your need for fabric-reinforced inflatable seals that are meant to squeeze, push, seal, lift, hold or stop. Our team is stacked with knowledgeable and experienced engineers who produce custom designs that are manufactured with the highest quality materials specified for your application.

Our solutions keep critical industries operating at their optimal pace, and we look forward to exploring how we can assist you with your project.

For more information do feel free to visit Inflatable Seal Application & O-ring or call us at +91 9833590390 to let us know you’re interested.

Add a Comment