Have you heard the well-known saying, “It’s very much like riding a bicycle”? A few abilities, once educated, are not neglected. Without the right elastic parts, nonetheless, even all that bike can’t convey you along streets or trails. You might have the option to keep up your equilibrium for some time. However, you will not get far riding on a metal edge. A punctured tire is unpleasant, and fixing or supplanting a bike cylinder can be testing.

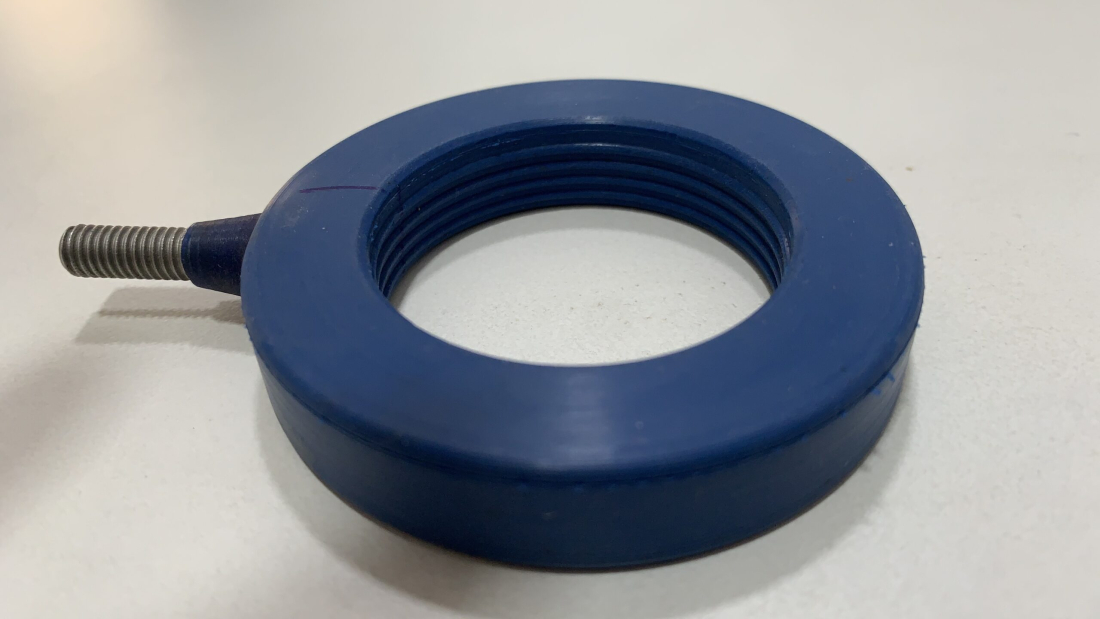

Wespo’ Inflatable Seals are elastic seals that blow up (as opposed to packing) to shape a tight hindrance between the mounting and striking surface and offer defilement verification fixing in a wide scope of uses. When contrasted with standard elastomeric seals, inflatable seals work adequately on unpredictable or skewed surfaces, which improves their fixing trustworthiness.

Inflatable seals are less complex to use as they request less power while ensuring 100% fixing.

Inflatable Seals Classification:

By Contraction

- Non-Reinforced Inflatable Seals: Non-supported inflatable seals are made uniquely from elastomers and are for the most part expelled developments; be that as it may, they can be shaped to meet explicit dimensional parameters. They are the favoured alternative for standard fixing applications as they are generally reasonable and don’t settle on quality and execution.

- Texture Reinforced Inflatable Seals: Molded texture built-up inflatable seals are suggested in applications including outrageous pressing factor/temperature conditions or rough conditions. The trim interaction kills joints and the texture support adds to the seal’s general strength and flexibility. Contingent on the application, one of the accompanying textures is picked

By Expansion

- Pivotal: Axially extending Inflatable Seals have the centerline width as the fixed measurement. The Inflatable Seal extends the opposite way concerning the distance across. These seals are in some cases likewise alluded to as face seals.

- Spiral Outward: Seals growing radially outward have the Air Inlet Valves(AIV) commonly introduced into a channel within distance across (ID) as the fixed measurement.

- Spiral Inward: Inflatable seals with little external widths may wind up wrinkling with this sort of development. Seals extending radially internal have Air Inlet Valves(AIV) commonly introduced into a channel with the external distance across (OD).

By Geometry

- Roundabout: Inflatable Seals with roundabout calculation are the most generally utilized seals inferable from their wide application. Roundabout Inflatable Seals are the for the most part liked in sewer vent covers, container seals, or in modern apparatus like fluidized bed dryers, autoclaves; wherein the machines are made in round measurements.

- Square shape: Rectangular Inflatable Seals are ordinarily found in entryway applications like entryways for tidying up rooms, atomic offices, satellite testing offices, and so on Kindly note, Western Rubbers’ doesn’t manufacture rectangular seals with tight radiused corners. This is to guarantee the seal development isn’t undermined anytime.

- U formed: U molded Inflatable Seals are a typical design in inflatable entryway seals. Closures of u-formed seals are vulcanized and henceforth can’t expand. The uninflated segment of the seal relies on the seal profile and application. Suitable maintenance instruments for this design are accessible at Western Rubbers.

- Strip: Inflatable seals with straight arrangements are most normally found in clips and actuators. Straight seals have vulcanized finishes that don’t grow. The measure of an uninflated region in straight seals relies upon profile and application. We give maintenance components that function admirably for straight seals.

Inflatable Sealing for Manufacturers:

Inflatable seals are utilized during tasks like the development of powders between drums or barrels. The sealing activity that these rubber parts give assists to prevent the deficiency of mass solids, ensuring item purity, and protecting personnel. Waste reduction is significant. However, manufacturers should likewise contain undesirable admixtures of various kinds of powder materials. Insufficiently high concentrations, as well, a few powders, can be explosive.

Applications for inflatable seals incorporate the powdered metals industry, pharmaceutical manufacturing, and food processing. To help contain metal powders, reinforced seals made of EPDM and neoprene are utilized since wear and abrasion resistance are significant. In the pharmaceuticals industry, FDA-supported silicones might be required. Given their high help temperatures, silicones are additionally used in broilers, where inflatable seals support automated fingers that snatch and move holders or items.

How Can We Help You?

Do you need to source inflatable seals for these or different applications? How might we help you? For a very long time, Western Polyrub has been working with partners in various industries to solve sealing challenges. By paying attention to the entirety of your necessities and investigating the whole of your requirements, our suppliers can suggest inflatable seals that are appropriate for your application.

If it’s not too much trouble, get in touch with us for more data, or join the discussion on our social media channels. Search for a post connected to this blog entry on LinkedIn, Facebook, Google+, and Twitter. Finally, please feel free to subscribe to our free e-newsletter. They’re an incredible source of info conveyed right to your email inbox, and they connect to blog sections like this one.

If you need more information, Please Feel free to Contact us

Himanshu Shah

Administrator

Western Polyrub India Pvt. Ltd

Add a Comment