HomeProductsExtruded Rubber ProductsSilicone Rubber Extrusion

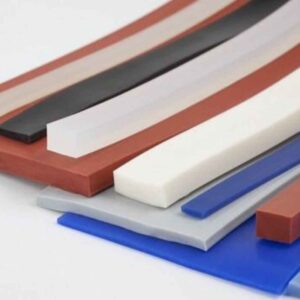

Silicone Rubber Extrusion

Wespo manufacture silicone rubber extrusion in any design in any shape in-house so that all our extrusion products perform to the highest standards of quality and meet a wide range of customer specifications and requirements.

Silicone Rubber Extrusion

Wespo make silicone extrusion with latest technology and well-equipped laboratory and in-house mixing facilities with rigorously test each batch before production and can adjust formulations to meet your unique needs.

Our western standard GP and other special grade materials offer all the resilience and versatility of silicone rubber and comply with a range of industry standards, such as those of the Food and Drug Administration (FDA), and EU framework directive EC1935/2004. Western polyrub extrusion range is available in A-scale shore hardness of 30 to 80. It is available in white, red, blue , green black and translucent as standard and we offer a colour matching service for special requirements.

Special Grades

In addition to the western GP range, we offer specialist products for more demanding or unusual environments.

GP – General Purpose

HT – High Tear

FR – Flame Retardant

THT – High Temperature

LCH – Low Smoke & Toxicity

FS – Fluorosilicone

TS – Tough

If you require any silicone profile then please do not hesitate to get in touch with our experts. We will be very happy to arrange a site visit at short notice to assess and discuss your requirements. We will then work as quickly as possible to design, prototype and produce a rigorously tested, industry compliant product.

WESPO Metadect – Metal Detectable Silicone Extrusion Available With Fda Certificate

WSDS (Wespo Static Dissipative Silicone) Extrusion Available With Fda Certificate

WESPO -electrical conductive silicone available in black colour

Wespo Silicone Extrusion Range :

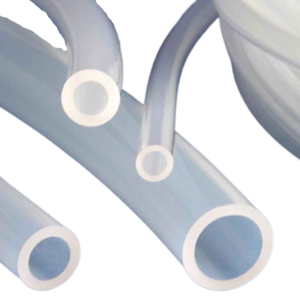

Tubing, Cord, Profiles & sections

Shore A hardness from 30-80

Available in translucent, white, red , black,blue, any colour

Colour matching available

FDA approved

Also available in low smoke, low toxicity (LCH) and flame retardant (FR), conductive silicone extrusion black and food grade also available.

leading manufacturers of fabric inflatable seal

Today western polyrub stand out as leading manufacturers of fabric inflatable seal who make seals with hand built and fully moulded with fabric reinforcement inside make seal so tough that can withstand pressure up to 50 Kgcm2 Fabric Reinforced Rubber Seals Are Effective Where Moderate- To High-pressure Is Applied(we make seal up to 50bar bursting pressure ) , Such As In Heavy Industrial, Environmental, Technical And Laboratory Environments,marine,nuclear Region A Variety Of Reinforcing Fabrics Are Available And Determined By Factors Such As Temperature And Pressure.

Fabric inflatable seal moulded

Wespo also provide fabric inflatable seal moulded with rubber nozzle for flexibility and longer life if clients demand Western Polyrub Offers Technical Guidance To Determine The Appropriate Design, Manufacturing And Material Composition. The Fabric Inflatable Must Withstand Environmental Factors And Perform Using Air Or Gas Controlled Mechanisms Under Pressure. The Environment And Structure Will Affect The Choice

OFFSHORE APPLICATION

Western polyrub has developed technology to used fabric reinforced inflatable seal in a number of critical applications including offshore production, storage and offloading (FPSO); anchoring drill rigs to the seabed; gas loading systems; pipeline welding; and watertight doors and panel High -pressure inflatable seals are designed to fit in metal retaining grooves, allowing axial, external radial and internal radial expansion, These seals typically can withstand pressures of up to 8 bar, and are suitable for sealing clearances from 2-10mm.

Advantages Of Silicone Rubber Extrusion

- Easy installation and routing

- Visual confirmation of flow in tubing

- Autoclavable with long service life in gasket

- Essentially non-allergenic, non-thrombogenic and reduced odor

- Compatible with most clean-in-place lines

- Compatible with clean-room manufacturing processes

- Low smoke and toxicity

- High Ash cohesion

Features (Properties)

- Flexibility

- Transparency and Translucency

- High-temperature Resistance

- High Resilience and elastic Memory

- Chemical Resistance Processability

- Biocompatibility

- Excellent mechanical properties including tear strength and elongation

- Ceramifiable Flame resistance grade

- Conductive black and food grade in colour

SKETCH DRAWING

Send your sketch or drawing

MATERIAL

Choose the Material

SPECIAL FEATURE

Add the special feature

FINAL PRODUCT

We will deliver your product quickly.