How To Choose the Right Self-Retaining Inflatable Seals for Your Application

Self-retaining inflatable seals are a popular choice for a variety of applications. They’re used in a variety of industries, including oil and gas, water resources, and transportation.

In this article, we’ll give you tips on how to choose the right self-retaining inflatable seals for your application.

We’ll discuss the different types of self-retaining inflatable seals and give you an overview of the different features that each type of seal has. We’ll also give you tips on how to choose the right seal for your application and how to install it.

What are self-retaining inflatable seals?

Self-retaining inflatable seals are an alternative to static seals. An inflatable seal is designed to fill with air when pressure is applied. When the pressure is released, the inflatable seal deflates. Self-retaining inflatable seals are a type of seal that rely on a compressor to fill them with air.

The compressor is typically powered by a battery. When inflatable seals are used in applications where there’s a high risk of the seal being damaged by external factors, such as the weather and vibrations, they’re a great option.

They’re also popular for use in industries that have a high risk of damage to their seals from human error, like aviation and the oil and gas industry. The inflatable seal’s ability to automatically fill when needed makes it a popular choice for applications like agriculture and construction.

Related Topic: How To Increase The Operational Life Of Inflatable Seals

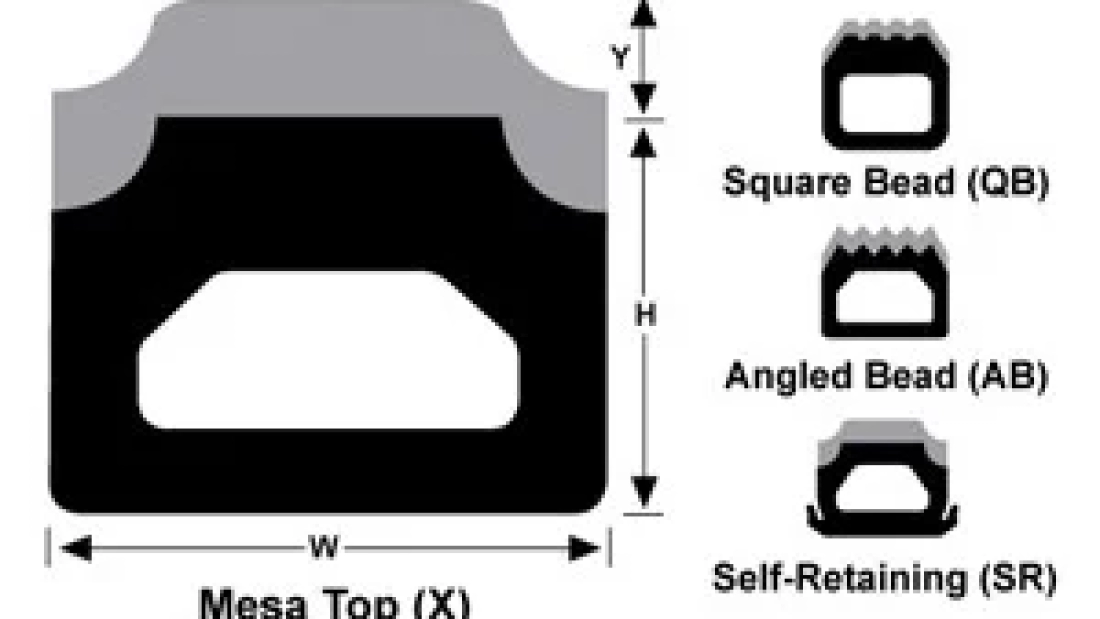

Types of self-retaining inflatable seals

Self-retaining inflatable seals come in two types

Positive and Negative pressure.

Positive pressure self-retaining inflatable seals can only be filled from the inside. They work the same way that positive pressure valves do. When pressure is applied to the seal, it draws air from the interior. When pressure is removed, the air inside the seal decompresses and exits through the orifice.

In some applications, like waste treatment, there are risks of negative pressure causing explosions. Therefore, a negative pressure seal is a safer option. Negative pressure self-retaining inflatable seals can be filled from the outside with air or liquid. When the seal is filled with air, the air pressure inside the seal keeps the orifice open. When the pressure outside of the seal is less than the pressure inside the seal, the orifice closes and the seal is filled. The seal can be filled with air from the outside, with compressed air, or with liquid.

What are the benefits of using self-retaining inflatable seals?

Self-retaining inflatable seals are a great alternative when there are a few specific benefits that you look for in a seal. These benefits include sealing applications that have a high risk of damage to the seal and applications where damage to the seal is highly likely.

- Sealing applications that have a high risk of damage to the seal

- This could include mining, the oil and gas industry, and the agriculture industry.

- Applications where damage to the seal is highly likely

- These could include aviation and the oil and gas industry.

How do self-retaining inflatable seals work?

Self-retaining inflatable seals use a combination of the principle of hydrostatic and compressive forces. When air pressure is applied to the seal from inside the application, the air inside the seal is under pressure. When the pressure is released, the air inside the seal decompresses and exits through the orifice.

In applications where the risk of damage to the seal is high, the seal is designed to automatically fill with air from inside the application. This ensures that the seal is always filled. In applications where the seal is more likely to be damaged by human error, such as aviation, the seal can be manually filled from the outside.

How to choose the right self-retaining inflatable seals for your application

When choosing a self-retaining inflatable seal, you’ll want to look at the risks of damage to the seal in your application and how likely that damage is to occur. In applications where the seal is highly likely to be damaged by human error, such as the oil and gas industry, the value of automating the seal can outweigh the risk of damage to the seal when using a self-retaining inflatable seal.

You can also look at the flow rate of the seal. In applications where the risk of damage to the seal is relatively low, you can find a lower flow rate in the self-retaining inflatable seals. In applications where you want a seal that can be manually filled from outside the seal, you can also find a seal that can be manually operated.

How to install a self-retaining inflatable seals

Before you begin installing a self-retaining inflatable seal, you need to make sure that the seal is designed for the application that you’re working with. In most cases, you’ll need to install a permit where the inflatable seal will be used. If the seal will be installed in a public area, such as a road or sidewalk, you’ll need to get a permit from the local government authority.

The seal will come with detailed installation instructions. It’s important to follow the instructions so that you can properly install the seal. If you choose to install the seal yourself, make sure that you wear safety goggles, a dust mask, and gloves. You can also use a sealed stand to make installation easier.

Conclusion

Self-retaining inflatable seals are a popular option when it comes to sealing applications. They’re a great seal option for sealing applications with a high risk of damage to the seal, as well as applications where damage to the seal is highly likely, such as the oil and gas industry. We’ve provided you with tips on how to choose the right self-retaining inflatable seal for your application and how to install it.

Find A Reliable Sealing Solution

Wespo can fulfil your need for fabric-reinforced inflatable seals that are meant to squeeze, push, seal, lift, hold or stop. Our team is stacked with knowledgeable and experienced engineers who produce custom designs that are manufactured with the highest quality materials specified for your application.

Our solutions keep critical industries operating at their optimal pace, and we look forward to exploring how we can assist you with your project. For more information do feel free to visit Inflatable Seal Application or call us at +91 9833590390 to let us know you’re interested

Add a Comment